This is a very old but never played/museum quality snare drum. From what I've dug up on my own, it's from 1909-1915. It's a metal Conn drum with wood hoops and has twin snares, one underneath the batter head and the other is on the resonant head. It still has the original heads on it and it was given to me by Bob Grauso of the Fibes drum company. He told me it was quite valuable and wanted me to have it. He also gave me other rare things before his passing that I wouldn't part with, but this particular drum he said was something I could sell. I've only found one sale of this drum and if I remember correctly, it only fetched around $250.00. I would think that this drum would be worth considerably more, but I could be wrong.

Read more1950s Leedy & Ludwig Broadway Set

I went in to the lovely home of the owner of this set. He is in his 80s, and after a few minutes of greeting I was taken to the set. It wasn't set up, but I was encouraged to set them up and play on them or whatever I wanted to do. I just enjoyed looking at everything. There was also a wonderful cymbal set included, some of them were "K" Zildjians. There were stands, other hardware, and a box full of great old percussion "stuff." After I had looked it all over, I sat down with the man and enjoyed a long talk with him. He has a life filled with great experiences and I'm glad I got to hear some of them. If I had left without the drums and only got to talk to this guy, I would still be richer from the experience.

Read moreThe Tuxedo & Black Beauty

“No Drum Left Behind" - the restoration of an engraved 1920sC.G. Conn Tuxedo and early 1930s Ludwig & Ludwig Black Beauty

There comes a time when every vintage drum collector finds a “diamond in the rough” and has to decide either to: 1) keep it original (but flawed), 2) do some restoration work, or 3) walk away from the deal. From a purist’s perspective, any change to a vintage drum will greatly diminish, if not destroy, its value. However, I would argue that there are times when salvaging a drum through expert restoration is truly warranted. Here are two such examples…

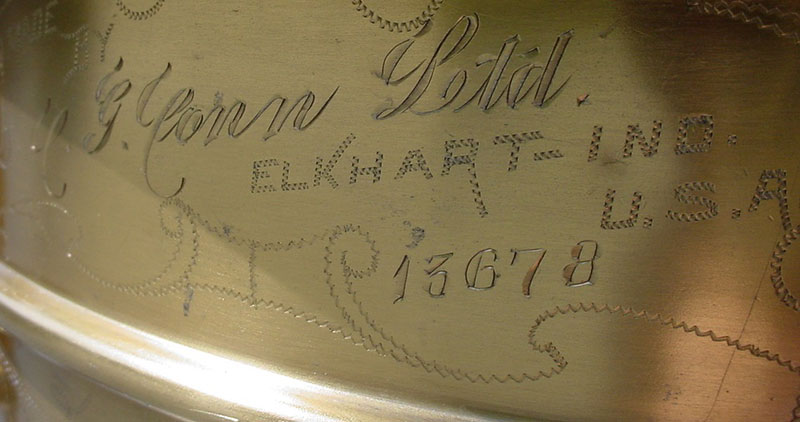

Some time ago, I stumbled across two such “rough diamonds” on Ebay. One auction had no other descriptor than “1920s-30s C.G. Conn 5X14 Brass Snare Drum.” I looked closely at the pics by eye and thought I saw some engraving on the shell. To examine it further, I downloaded the auction pics and zoomed in using Photoshop. Lo and behold, it looked like a 1920s C.G. Conn engraved Tuxedo with the characteristic four diamond cross pattern! The inside of the shell still retained the black nickel so I was pretty certain the outer black nickel plating had been removed. I won the auction for a very reasonable amount, so the thought of black nickel re-plating seemed like a worthwhile investment. When the drum arrived, my presumptions were confirmed. It was indeed an 8-tube lug, 1920’s Conn Tuxedo with “Made by C.G. Conn LTD, Elkhart, IN U.S.A.” stamped on the upper hoop, 4-screw “Presto-like” strainer, Knobby Gold hardware and shell engraving in beautiful condition. Next, I set about to do some research on what it would take to properly restore this drum. I needed to think long and hard about this, as it required additional investment and had to be done correctly if done at all. Meanwhile, another orphan drum serendipitously crossed my sights on Ebay.

This time, the drum was clearly identified as a “1920s-1930s engraved Ludwig Black Beauty.” The early 1930s art gold hardware looked amazingly well preserved for its age: 10 brass tube lugs, timepiece strainer; smaller, more rounded snare gates, “Super-Ludwig” embossed on the bottom hoop in block letters. The logo engraved on the shell was somewhat unusual, reading “Ludwig – Trademark” rather than the usual “Ludwig, Chicago U.S.A.”, and bounded by a rectangular box (actually, a parallelogram as I was corrected by my daughter) one panel to the left of the strainer. The catch was that the engraving was thoroughly blackened with none of the brass visible. During its lifetime, the drum had either been painted black or poorly re-plated. I took a gamble and placed a winning bid, hoping that there was some original black nickel underneath. When I got the drum, I sent pics out to Mike Curotto and Harry Cangany for their thoughts on the shell. None of them could be certain from the pictures whether it was black paint or nickel. So off the drum went to Mike Curotto’s shop for closer examination. A short time later, Mike gave me the unfortunate news - the drum had been painted and no black nickel remained.

This now left me with two wonderful vintage drums whose hardware was in great shape, the original engraving intact, but stripped down to the brass. I consulted Harry Cangany about restoration, weighing the concerns of valuation/devaluation vs. preservation. I finally came to the conclusion that these two drums needed to be brought back to life, to the way they looked in the 1920s and 30s (fortunately, Harry agreed ☺). This was not about vintage drum investment but more so about preserving our drum heritage.

I was convinced re-plating was the right thing to do. So, I contacted the amazing drumsmith, Adrian Kirchler (“AK”), in Italy. I was aware that AK not only made great drums for Ludwig (100th Anniversary Triumphal) and Craviotto (AK/Craviotto Masters Metal series, 10th Anniversary Black Diamond) but also was the only craftsman in the world who could re-plate engraved drums and leave the engraving shining brightly through the black nickel. Mike, who had the drums in his shop, kindly sent them shells to Adrian for re-plating. Mike kept the hardware to polish/buff up and spray a coat of clear lacquer. As Mike says, “rust never sleeps."

About six weeks later, the drums arrived at my home. I think the pictures speak well to the outstanding work of AK, together with the gentle, expert cleaning by Mike Curotto. I have no regrets. The drums are beautiful. They have been kept intact with original or period-correct hardware and original engraving. However, now the artistry of the engraving glistens against contrasting dark, black nickel as it once did almost century ago. The drums are whole again. I feel content that two drums have been saved from the scrap heap, and now serve as gleaming historical artifacts of early drum craftsmanship. I guess it’s the next closest thing to a time machine… I just wish I could bring back the original owners in order to hear how the drums sounded in their hands. I’ll just have to settle with playing them myself and pretending…

Best wishes, Bob

Many thanks to Harry Cangany, Mike Curotto and Adrian Kirchler who kindly provided guidance, encouragement and their talents to this project.

1920s C.G. Conn "Holey"

Hi all,

This one took some serious rescuing. My friend and fellow collector Robert Campbell bought this drum a while back and contacted me for my opinion on what to. My advice (if he wasn’t into the drum for too much money) was to repair, restore and preserve the drum as best as possible. Bob agreed, the following is what took place.

1920s C. G. CONN 5 x 14 SILVER PLATED/GOLD PLATED/ENGRAVED 6 LUG ALL METAL SEPARATE TENSION DRUM

The Shell: The good news is that the shell is silver plated, gold plated and nicely engraved. The bad news is that there were 15 extra holes! Yep, 15 collector-cringing extra holes.

Can you “splain it to me Lucy” why anyone in their right mind would drill 15 extra holes in this special order, gold plated and engraved shell? Extra ventilation, oh of course, how silly of me. The first stop was to get the shell into the golden hands of my welder/machinist Abe Abello of Weld-Tec in Redwood City CA. There were so many holes in this shell that I had to tape off the 17 original holes that were not to be plugged. Abe was able to plug the holes but I explained to Bob that due to the excessive heat needed to do the plugging correctly the silver and gold plating was burnt away in the areas near the extra holes. Enter Les Hagnagy of Avenue Plating in Redwood City CA...less than 50 yards away from Abe. Les tried his best to use a technique whereby he “rolls on” the gold plating just to the affected areas via a “wand” that is hooked up to the gold plating tank. Unfortunately the shell was too far gone from the extensive hole plugging that had to be done so the decision was made to simply re-gold plate the shell. After a nice clear coat the shell was brought back to life. One last interesting oddity was that the bead on the shell looked normal from the outside but on the inside you can see that there was no channel but rather a very small opening, definitely different from the Ludwig & Ludwig/Leedy shells of the same era.

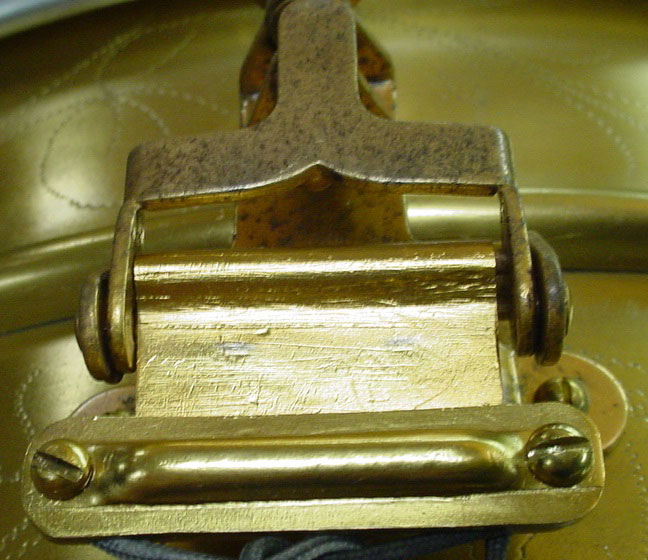

The Hardware: The good news is that the hardware is gold plated. The bad news is that although you could see the gold plating on the steel rims, tension rods, collar hooks, Utility strainer and butt plate... everything was heavily rusted. The 6 brass tube lugs were fine but the gold plating had long since worn away. Les dipped all of the hardware into his cleaning tank and removed the rust but we decided to flash gold plate the hardware as there was too much rust damage. Les clear lacquered the hardware to preserve the gold plating and to at least stave off any future rust. There were two missing tension rods. These were not your normal sized tension rods but instead they were 10-24 threads with very small square heads. I had two copper plated 10-24 T-handle tension rods in my parts stash, that’s a little bit of luck on my part but the real miracle is that Abe was able fabricate two matching tension rods from what I had. I was so amazed that I had to add a photo. The Knobby Gold Leedy T-handle on the right is an example of the two that Abe had to work with, the two tension rods to the left of the T-handle are the fabricated tension rods from Abe.

Tensioning was a bit of a chore as these 10-24 C. G. Conn tension rods had very small heads so I went to my vintage key collection and found a few banjo/clock keys that worked perfectly; one key is for you Bob just in case you ever want to change heads. The Utility strainer and butt plate were quite different as compared to what we would normally see on Leedy drums from the same era (see photos). The steel band rims were in the worst condition. Les was able to remove all of the rust but the “etching” from the rust remained even after the gold plating.

I was glad that Bob wasn’t into the drum for that much money as I would have hated to see this piece of C. G. Conn history just die by the wayside. The real heroes are Abe and Les. I am very fortunate to have them associated with my hobby. Their work continues to amaze me!

Enjoy.

Mike Curotto (Drum Whisperer)

Leedy 1940s Drum Set

Hello, vintage drum friends. I just love the old drums, and I'm sure many of you love them too. If you didn't you probably wouldn't be reading this magazine. There's just something special about the drums built in the 20s through the 40s. Most of the drums I own are from the 50's through the 70's. Those really appeal to me the most because those are the drums I grew up playing and wanting. The same is true of cars. I really dig the 50's through the 70's cars the most, but the pre 1950s cars are also very cool to me. Just like the really old cars with the big fenders, the really old drums have a special awesomeness about them. Those big bass drums and the sound of those old "tubs" give me goose bumps. I have a set to show you that I think has a great old vibe and I think you'll love them. It is a set made by the great Leedy Mfg. Company. They have a 1941 date inside. So they were built just before the United States entered into Word War II.

Leedy was one of the great American drum companies, and their drums were known for excellent quality. They were a very innovative drum company. The first drums they made were built in Indianapolis. The 20s were a wonderful time for the company. Leedy products were very popular. U.G. Leedy, the founder became sick and sold the company to Conn in 1929. The Leedy drums were made in Elkhart, Indiana beginning in the 30's. This kit has Elkhart badges. Throughout the 30s and 40s Leedy drums demonstrated American craftsmanship at its best. I recommend you read "Mr Leedy and The House of Wonder" by Harry Cangany for the story of the "World's Finest Drums".

This set is a matching four piece set in a beautiful Cream and gold Duco finish. More than likely painted by Mr. Ray Poland who worked in the finishing department for many years. I just love this finish. I wish I had the skill to paint drums like this. The sizes are: bass drum 26"X14", the small tom is "11X7", the large tom is"13X9", the matching Reliance Snare is "14X6.5". The toms have tacked calf bottom heads. The hardware is nickle plated. The toms have Beavertails on top with single flange rims and hooks. The bass drum has single tension with thumb rods. The rod passes through a bridge on the bass drum that matches the Beavertail lugs .The snare has 8 tube lugs, single flange rims with hooks, and the Presto strainer. These drums still sound great. They are a work of art as well as a great musical instrument. The metal mounting bar on the bass drum is very cool. All this metal was not allowed on the metal restricted war time drums that followed this set.

I went to buy a Ludwig Deluxe (Black Beauty) from a fellow collector. He was selling the snare for a well known recording and touring drummer. He showed me this Leedy reliance snare drum and told me the complete set was for sale if I was interested. I was unable to turn down the Leedy kit once I saw the snare drum. I ended up buying the Ludwig Deluxe and the Leedy set. I was very excited about the buying trip until I thought about how I was going to explain it to my wife. I surprised her once by coming home with a Rogers kit and a Slingerland kit we had not discussed. It took a while to explain to her what a great deal it was. Fortunately, she was very understanding, and she really liked the Leedy set. Who could resist loving a beautiful Leedy set like this? Until next time keep looking for those drum treasures.

1923 Conn Engraved Snare Drum

Hi All,

This is my first article on NSMD. I’m a drummer in Chicago and happened upon what turns out to be quite a cool drum.

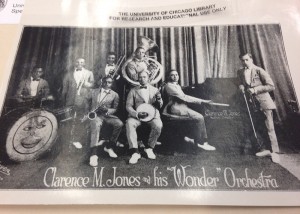

Here’s the story: I was checking out a local vintage clothing/thrift shop in my neighborhood a few months ago. I saw this beat up looking old metal drum sitting on a corner shelf. At first I thought it was possibly an old antique toy drum for a child, but up close I saw that it was a Conn. I was more interested but was still thinking to myself if it was a Ludwig or something maybe I’d buy it (I didn’t know too much about Conns.) Then I noticed all the cool engravings including one that read “Frank Biggs 1923.”

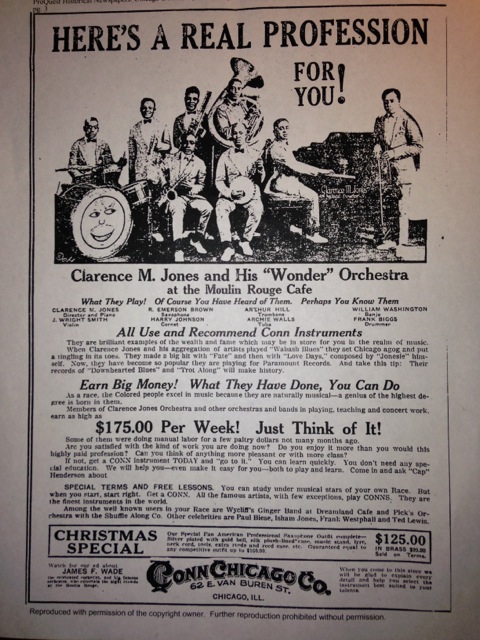

So, I thought I better at least google Frank Biggs. It turns out Biggs was a popular jazz drummer in Chicago in the 1920s onward..He is credited as writing “That’s When I’ll Come Back To You” recorded by Louie Armstrong’s Hot Seven. There are some articles and announcements of him playing at different Chicago Jazz hotspots, etc... including a great ad for Conn from 1922 with his photo in it (maybe that’s the drum?)

So, the jazz buff in me wanted that drum just for the cool story behind it. It’s always cool to find out where an old instrument came from. I went right back and bought it for not a whole lot of money. My initial thoughts were to restore it, play it, and bring it back to life.

On to the drum itself, this past week I contacted Adrian Kirchler, Harry Canangy, and Mike Curotto. All of whom shared their expertise with helping me further identify this drum. Turns out it’s a custom made, custom engraved gold plated Conn Victor Model. A real “gem” as Adrian called it, a one of a kind. And while it’s not a Leedy, Ludwig or Slingerland, it’s really a neat piece with a cool connection to early Chicago jazz. Maybe not the best idea to take out on various gigs?

There’s a bulb fixture still in tact, all the lugs, rims, and shell are in great shape, actually. Also, Frank Biggs signed his name backwards on the inside of one of the heads presumably to illuminate his name through the bulb. It’s still completely legible.

There are some extra mounting holes by the strainer. There’s a higher end Ludwig strainer on the drum. The question Adrian had was whether or not Biggs ordered the drum with the better strainer or had the standard utility model removed and replaced it with the better Ludwig. An interesting thought…

Well, enough words, here are some pics:

Hope you all enjoy the drum. Feel free to email me if you have any more info, fun facts, etc... Jbatchko@hotmail.com. Again I’d like to thank Adrian, Harry, and Mike for their great help. And to Chicago pianist/sleuth Steven Heliotes for finding all the interesting info on Frank Biggs. And thanks, George.

Cheers, Jason

Splitting Hairs

“A rose by any other name would smell as sweet”… a famous Shakespearean quote from Romeo and Juliet. What has that got to do with drums you ask? I know I am beginning to sound like a “One Note Samba". As noted in my last NSMD submission, I am no Ludwig expert BUT it occurs to me that a commonly used reference of “transition badge” is, in fact, a misnomer. The badge above on the left has the reigning title, but the one on the right smells sweeter to me.

A little history…The Ludwig & Ludwig Drum Company was founded in the spring of 1909 by brothers William F. and Theobald Ludwig, manufacturing a bass drum pedal. Crude pedals of the day were “…not powerful or fast enough for the fast rag-time tempos” and the new Ludwig creation became an immediate success. So much so that the brothers began spending more time manufacturing rather than playing drums. That is, until Theobald fell victim to the great Flu Epidemic in 1918 and died at a young age of 29. By demand, William F. took over and devoted 100% of his professional career to manufacturing. Ludwig & Ludwig became the world’s largest drum company in the 1920’s, surpassing Leedy Drums. World War I put a damper on all non-war related manufacturing, but Ludwig was awarded a substantial contract from the US Government for rope tensioned drums and the company continued. After the war, returning musicians were in-demand for theater orchestras and Ludwig’s success flourished.

From William F, Ludwig Sr.’s booklet, 75 Years A Drummer…My Life At The Drums:

“In 1929, as the well-remembered depression drew near, some of us became, perhaps unduly, concerned about the future. The Stock Market collapse choked business and we owed money on our new building (built in 1923). After considerable deliberation, it was decided that the best way for Ludwig & Ludwig to ride out the storm would be to merge with the G.C. Conn Co. of Elkhart, Indiana.”

The Conn Company was already cash-strapped from the purchase of the Leedy Drum Company earlier. Conn proposed a merger with Ludwig receiving $1,000,000 of preferred Conn Stock. Facing bankruptcy, Ludwig was forced to accept. Unfortunately, the Market crash devalued the option to $100,000. Ludwig, being the eternal optimist and being at odds with the Conn business model (which included not only another drum company but a full line of musical instruments) decided,

“In the year 1937…to start all over again in the drum manufacturing business and bought the 20,000 square foot factory building at 1728 N. Damen Ave. in Chicago…The new firm was named the Wm. F. Ludwig Drum Co.”

Conn was quick to notice and had their attorneys file for trademark infringement (Conn owned the Ludwig name). Ludwig Sr. was forced to change the company name to WFL Drum Company. Knowing the brand recognition of the Ludwig name, he wisely inscribed his logo badges to include “Wm. F. Ludwig, Founder”. Conn was enraged but Ludwig was totally within his right, a totally legal procedure."

Son Wm. F. Ludwig, Jr. joined the company one year later and albeit a slow start, the WFL Drum Company began to grow. World War II soon erupted but with some innovate designs to overcome the ensuing government metal restrictions together with Ludwig’s uncanny ability to secure government contracts, the WFL Drum Company received “the largest contract for field drums that had ever been placed with a single manufacturer.” Post war sales flourished with the war-weary population turning to music to relieve their depression. That coupled with the signing of Buddy Rich as an endorser, WFL, with Ludwig at the helm, became a major contender once again. Rich’s endorsement was not without pain though. WFL Jr. later recounted,

“My six most feared words were ‘Buddy Rich is on line two.'”

Still, the path was definitely silver lined, especially when Ludwig Sr. got the call of his dreams. Conn had a number of set backs including a 110 day strike of their labor force. In 1951, in an effort to consolidate their efforts they merged the Leedy and Ludwig & Ludwig names to offer the Leedy & Ludwig Drum Company. By 1955, lack of direction coupled with some design failures forced Conn to reconsider keeping drums in their instrument offering. The decision was made to sell the drum line…the Leedy name to Slingerland, the Ludwig name would go full circle, back to the Ludwig family. Ludwig Sr. continues,

“after exactly twenty-five years…I ‘owned’ my own name once more!”

That same year WFL offered a new catalogue with Buddy Rich proudly displayed on the cover and a WFL badge that still contained Wm. F. Ludwig, Founder at the bottom. The drums produced at this time however (with some exceptions) had badges that were stamped “WFL” at the top and “Ludwig Drum Co Chicago USA” at the bottom. The 1957 catalogue includes a WFL badge with this “Ludwig Drum Co. Chicago USA” inscription at the bottom. This continued until 1958 (I have seen 1958 date-stamped WFL drums with this badge). Then about 1959 the so-called “transition stamp” badge appeared with “Ludwig” at the top and “Drum Company” at the bottom. My question is, why is this the “transition badge” when the prior badge was emblazoned with “WFL” and Ludwig”? Isn’t that clearly the transition? When both names are included after the acquisition from Conn in 1955? I clearly remember in 1956 (see the April 2013 NSMD article “Taking the Driver’s Seat Of A Time Machine”) when the proprietor of Ballou’s Drum Shop in Dayton, Ohio, where my parents bought my set of WFL’s exclaimed, “Those drums are now being made by the Ludwig family.” It was a big deal at the time.

My take on it is, Ludwig was a great promoter. He also knew the value of brand recognition. After building the Ludwig name, only to have it taken away, he again built the WFL name (with the help of including his name as the founder). After seeing the Ludwig name denigrated by poor decisions and marketing by the Conn Company, he realized a quick name switch from WFL to Ludwig was definitely not in order. Though he was ecstatic to “own his own name once more!”, he wisely made the badge transition over a three year period that included both the WFL and Ludwig names. I know there are those that will fall back on the “they used whatever was available” theory. There is validity to that theory when applying it to parts like footboards and throw offs…sure, use up the remaining old logo parts but badges? This is the hallmark of the company. Ludwig’s emphatic reclaiming of his name, yet with proper marketing savvy, would contradict. Yet, almost all historical accounts mark the blue label badge as the first “Ludwig” badge after the reclaiming of the Ludwig name in 1955.

1936 L&S Catalog (Leedy & Strupe)

In October, 1929, an ailing U.G. Leedy sold Leedy Manufacturing to band instrument giant C.G. Conn Ltd. For the next 9 months, Leedy drum building was in a state of transition. In August of 1930, the Elkhart factory was up and running. In those intervening months, Conn sent in a supervisor, Ed Cortas, and many employees came and went. Leedy himself hoped that his 100 loyal employees would have jobs in Elkhart, but many of them did not or could not or, more probably would not, move. U.G. decided to create another company called General Products. Concerned that the Depression would not bring in drum sales, Leedy wanted General Products to make other products as well. But, they would make drums. The legend has become fact. He wanted to name the company Leedy & Sons. He had two sons—Eugene and Edwin, later called Hollis. Conn had just spent $900,000 in cash to buy the Leedy name, so there could be no use of that name outside the drums now made by Conn.

Best place to order essay online.

I have only seen one Strupe drum, but have seen publicity shots of others.

Mr. Leedy bought a former dairy building and started the process of turning it into a drum factory. Some of it was completed when he died in January, 1931. His widow gave this fledgling company the funds to complete the woodworking shop. Edwin joined as Secretary Treasurer. Eugene did not become involved.

Leedy and Sons became L&S and we now think that L&S also stood for Leedy & Strupe. One of the former key Leedy employees who did not leave Indianapolis, at that point, was Cecil Strupe, the engineer. He was named president of L&S. In the earliest days of production, there were also Strupe badged drums. It may have been an attempt to circumvent the Leedy name while promoting Strupe’s name since he was known to drummers thanks to frequent mention in the Leedy Topics.

Today’s catalog was made in 1936. It is the only L&S I have found. I have seen brochures, and I think this company deserves honorable mention in American Drum History. L&S drums were sold nationally by mail through Chicago Musical Instruments. Chicago Musical Instruments had formerly sold Ludwig & Ludwig drums through their catalog, but that deal soured when Conn bought Ludwig as well. So, the catalog sales company needed a new drum supplier. If you lived in Indianapolis, you could stop by the factory and buy from their showroom. Famed California jazz drummer Benny Barth, told me about that. An L&S snare was his first drum. L&S made drums, timpani, bells and other mallet instruments, but the products just always seemed a notch below Leedy in quality. You can see imperfections in the cast lugs, from the dies. The drum rods were hex headed, calling for a special key. I would say that like the Cecil Strupe designs for Leedy, we see the same kind of toggle crazy, and thin metal/weak spot strainer inventions on L&S snare drums.

The popular high end snare drum during the middle years was called the Dictator, which was probably not a wise choice during the Hitler and Mussolini years. I see example of L&S drums pretty regularly on eBay and they seem to come from all parts of the country, which may give proof to the scope of sales from Chicago.

The company was never a success, but it hung on and had an interesting ending. Strupe left the company and moved to Chicago where he went to work for WFL. Edwin Leedy sold the company to a music store owner who marketed the ready made products through his store. He changed the name to the Indiana Drum Company. At some point in the early 40s, Sears and Roebuck had a connection with Indiana Drum, using the name Drum Master and then may have bought the machinery and designs. Sears advertised that they had a factory in Chicago, and, in the one Sears Drum catalog I have seen (check out Drumarchive.com to see it), you can see L&S drums, no matter what they were called.

I am sure World War II ended Sears' need to have a drum manufacturing plant. After the war, they struck deals with Kent and Japanese manufacturers to have drum sets for sale in their catalogs.

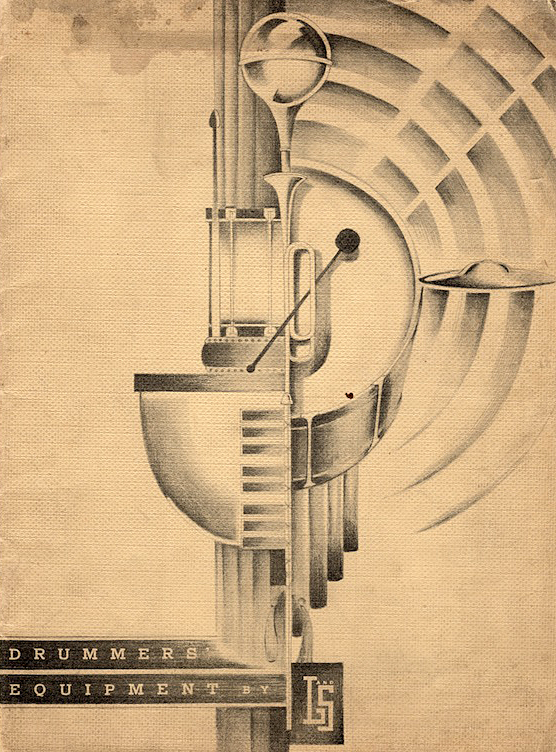

But for 10 years, Leedy Indianapolis alums were building L&S "Drummers Equipment” and hoping for the best.

-Harry