Hi all,

This one took some serious rescuing. My friend and fellow collector Robert Campbell bought this drum a while back and contacted me for my opinion on what to. My advice (if he wasn’t into the drum for too much money) was to repair, restore and preserve the drum as best as possible. Bob agreed, the following is what took place.

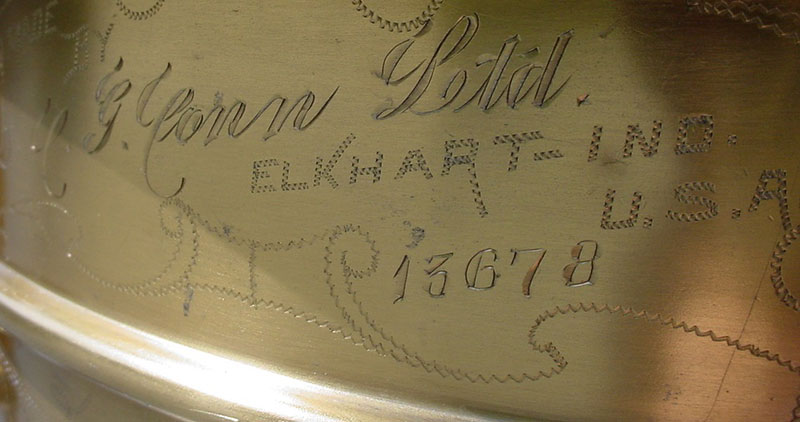

1920s C. G. CONN 5 x 14 SILVER PLATED/GOLD PLATED/ENGRAVED 6 LUG ALL METAL SEPARATE TENSION DRUM

The Shell: The good news is that the shell is silver plated, gold plated and nicely engraved. The bad news is that there were 15 extra holes! Yep, 15 collector-cringing extra holes.

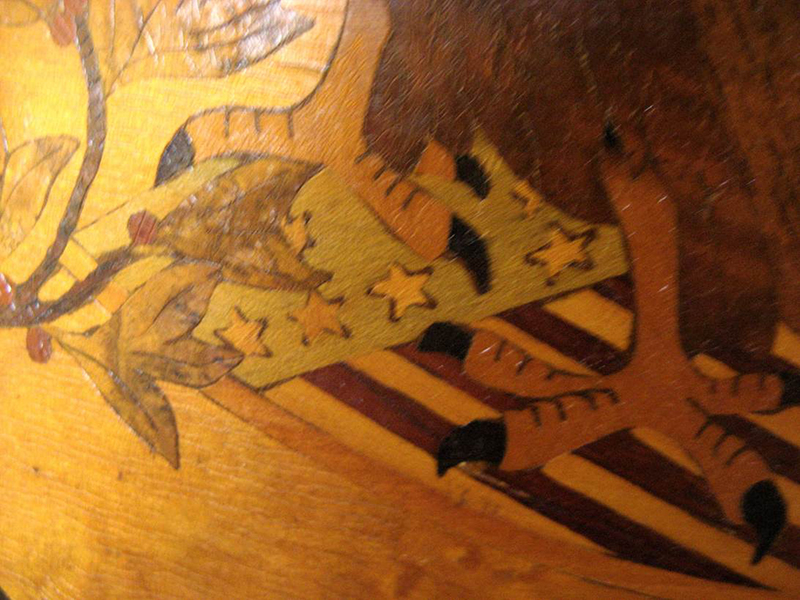

Can you “splain it to me Lucy” why anyone in their right mind would drill 15 extra holes in this special order, gold plated and engraved shell? Extra ventilation, oh of course, how silly of me. The first stop was to get the shell into the golden hands of my welder/machinist Abe Abello of Weld-Tec in Redwood City CA. There were so many holes in this shell that I had to tape off the 17 original holes that were not to be plugged. Abe was able to plug the holes but I explained to Bob that due to the excessive heat needed to do the plugging correctly the silver and gold plating was burnt away in the areas near the extra holes. Enter Les Hagnagy of Avenue Plating in Redwood City CA...less than 50 yards away from Abe. Les tried his best to use a technique whereby he “rolls on” the gold plating just to the affected areas via a “wand” that is hooked up to the gold plating tank. Unfortunately the shell was too far gone from the extensive hole plugging that had to be done so the decision was made to simply re-gold plate the shell. After a nice clear coat the shell was brought back to life. One last interesting oddity was that the bead on the shell looked normal from the outside but on the inside you can see that there was no channel but rather a very small opening, definitely different from the Ludwig & Ludwig/Leedy shells of the same era.

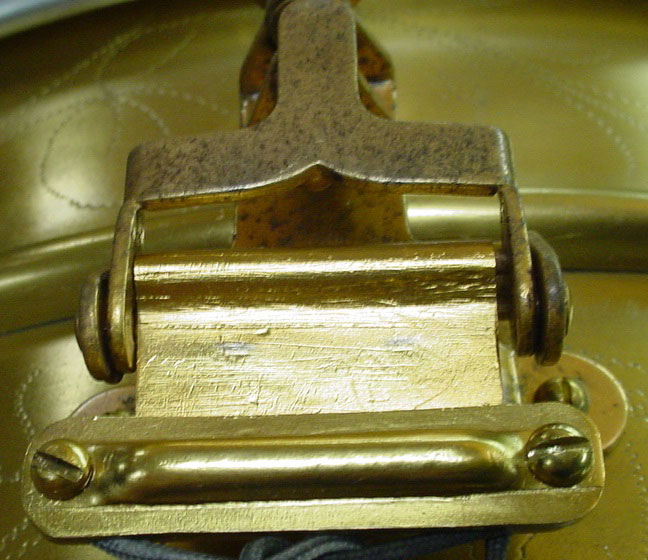

The Hardware: The good news is that the hardware is gold plated. The bad news is that although you could see the gold plating on the steel rims, tension rods, collar hooks, Utility strainer and butt plate... everything was heavily rusted. The 6 brass tube lugs were fine but the gold plating had long since worn away. Les dipped all of the hardware into his cleaning tank and removed the rust but we decided to flash gold plate the hardware as there was too much rust damage. Les clear lacquered the hardware to preserve the gold plating and to at least stave off any future rust. There were two missing tension rods. These were not your normal sized tension rods but instead they were 10-24 threads with very small square heads. I had two copper plated 10-24 T-handle tension rods in my parts stash, that’s a little bit of luck on my part but the real miracle is that Abe was able fabricate two matching tension rods from what I had. I was so amazed that I had to add a photo. The Knobby Gold Leedy T-handle on the right is an example of the two that Abe had to work with, the two tension rods to the left of the T-handle are the fabricated tension rods from Abe.

Tensioning was a bit of a chore as these 10-24 C. G. Conn tension rods had very small heads so I went to my vintage key collection and found a few banjo/clock keys that worked perfectly; one key is for you Bob just in case you ever want to change heads. The Utility strainer and butt plate were quite different as compared to what we would normally see on Leedy drums from the same era (see photos). The steel band rims were in the worst condition. Les was able to remove all of the rust but the “etching” from the rust remained even after the gold plating.

I was glad that Bob wasn’t into the drum for that much money as I would have hated to see this piece of C. G. Conn history just die by the wayside. The real heroes are Abe and Les. I am very fortunate to have them associated with my hobby. Their work continues to amaze me!

Enjoy.

Mike Curotto (Drum Whisperer)