Where did your interest in drum construction begin?

[Bill] “I started around 1982-83. I was building drums just for myself; nothing was done for customers. It was just me basically learning how drums worked – buy a drum, take it apart, learn how to change it, fix it… At that time, the only place you could get any real information on drums was through Modern Drummer magazine. I would read articles about drum techs like Paul Jamieson - what he said he would do with Jeff Porcaro’s drums; and Pat Foley, he was doing a lot of customization at that time here in L.A. I would read about what they were doing and try to emulate it. I just listened, read and jumped in with both feet. I started buying old drums, mostly snare drums, that I found in a local L.A. paper, the Recycler. For example, if I read in Modern Drummer about packing lugs with felt so you wouldn’t hear the springs rattle, I would tear it part and do that. I’d also clean all the hardware, replace screws, refinish it if needed, learn how fix or replace any broken parts, then put it back together and sell it.”

How did this interest progress to actually building drums?

[Bill] “In the back of Modern Drummer (around 1985-86), there was a small ad from the Corder Drum Company for a snare drum kit. This was basically all the parts to put a drum together – shell, lugs, throw-off… basically what Precision is doing now. I didn’t like the Fibes throw-offs with the big handle that came with the Corder kit, so I would add a Ludwig P-85. My father taught me how to shoot lacquer, so I was able to do the finish; then I taught myself how to cut bearing edges. I learned what snare beds are, how they work, and why a snare drum needs them. So I put it all together with the P-85, my beds and my finish, and sold it. I first bought two of these Corder kits, then I bought four, and then started buying shells from Keller. It kind of grew from there.

Now I had been working at Rocketdyne in L.A for 5 years, a company that made the main engines for the space shuttle. I really didn’t like the job so I was looking for anything that was a release from working there. To be clear, when I started Pork Pie, there was never a thought that I would able to one day making a living out of it. I went and got my business license, checking account with the business on it, and started to do little jobs for people. It got more and more busy over time. In late 1987, I received a call from John Good at D.W. saying they were getting ready for the NAMM show but unexpectedly were short-staffed and needed some help. He had to get all his stuff finished so they could take it to the trade show. I had a lot of vacation time, so I took that along with Christmas vacation, and spent about 4 weeks helping them get ready for the NAMM show. After the NAMM show, I started working for D.W. part-time. At the end of each day, I would leave Rocketdyne, drive out to D.W., and work 3-4 hours. Then I would come home and work on my own stuff. It got to the point where I just couldn’t function any more. I was just tired all the time. So I went to John (Good) and said, “Here’s the deal. I’m doing all this stuff and I can’t do it anymore. You need to make a decision; are you going to hire me or I have to go, one of the two.” So he said, “Let me talk to Don.” So they talked and decided to make me an offer to work full-time. I was thinking, “Thank God – now I can quit working at Rocketdyne finally.” So I worked there a painter; all I did was paint. I lasted around one year. I remember the moment I decided to quit and do this (Pork Pie) full-time. It was a Sunday in early June, 1989. I called my mother and said, “I just want to let you know. I’m going to quit my job tomorrow.” You could hear the panic in her voice as she said, “Oh my – are you going to be able to do it?” I said, “I have no idea, but if I’m going to do this, now is the best time.” I didn’t have a girlfriend at the time, my car was paid off; I had only rent and a dog to feed – these were my only bills. I figured if I was going to do this, it was the best time.

This leads to a really funny story (although maybe not so at the time). For my very first job being self-employed, a guy named Jim Carnelli brought me a brand new 5 X 14” Noble & Cooley snare drum in black lacquer to do edges on it. He was in the garage watching me work; it was really hot. I’m cutting the edges on my little router table and my hand was sweating from the heat. Somehow that brand new, solid, one-piece maple shell slipped right out of my hand right onto the router blade, taking a huge chunk out of the edge. So I’m thinking, “This is how it starts. You become self-employed and you screw something up on your first day.” I turned the router off, explained what happened to Jim and showed him the chunk missing out of the edge. Jim looked at it and said, “So – what do we do?” I said, “It looks like I’m buying you a new drum.” So on the first day I was self-employed, I had to buy a new Noble & Cooley snare drum to replace the one I messed up. Later, I took the drum I screwed up to a machinist; we squared off the area that had the big chink missing out of it, made a plug of maple and glued it in place. I let it sit for a few days, filed it close and then re-cut the edges. Mike Fasano has this drum and it’s one of the drums he rents out all the time.”

How did you come up with the name “Pork Pie Percussion”?

[Bill] “My friend Mark and I were sitting at my house, and we were trying to think of a good name for a drum company. We had been sitting at my house, watching this movie from New Zealand called “Goodbye Pork Pie” and I just said, “What do you think of Pork Pie Percussion?” Mark goes, “It’s great!” It was right up his alley; he’s a nutty, super-creative kind of guy. That was it – a consensus of two!”

Tell me a little about the drums that Pork Pie Percussion makes?

[Bill] “In the beginning, it was mostly maple because that was all you could get from Keller; that was all they made. There was Jasper (maple/gum ply shells) but their minimums were too high. It’s always been hard to get birch shells from Keller. At the time, there were three of us making custom drums: myself, GMS and Joe Montineri. Joe did get one run of shells from Jasper but it was really only Keller at the time. Later, some guys came out of the woodwork and starting making solid, one-ply shells. I got some shells from a guy in Connecticut, Glen (Paquette?). If I remember correctly, I got some oak and ash shells from him. For a while, I got some stave shells from Greg Gaylord, before he started working for Craviotto. We had a deal where, for every shell he would supply me, I would finish a shell for him. Just a couple of years ago, I started getting shells from Carerra in the U.K. I was getting walnut and mahogany and all kinds of different shells from him. Around that time, I started making the wood/brass shells that now everyone seems to like so much. The sad thing is that Carrera are closing their doors (Note: March 31, 2015; just two days after this interview). Dave Carrera has got a really bad lung condition. Fortunately, all of the tools and molds were purchased by North Custom Drums. One of the guys who used to work at Carrera is now working for North, so they haven’t missed a beat.

But in the early days, we had to be very creative. When I started to make 10” snare drums, there were no suppliers of 10” snare side hoops. Everybody takes that for granted now. There were no 10” snare wires either. For my first 10” snare drums, I drilled holes in a snare side hoop with my drill press, so I could have a gate for the snare strap to go through, and hand file the whole gate down. That’s what we had to do back then. After that, I had a machinist cut out a slot in the hoop for the gate. For the 10” snare wires, I had to take 14” wires and cut them down. Sometimes re-soldering didn’t work well because of the chrome plating so I would use epoxy to hold the snare wires in place.”

You’ve also made a series of metal shell drums – could you tell me more about these?

[Bill] “The shells for the first Pork Pie metal drums were made by a friend, Larry Gill. I haven’t seen him in years. He was a metal sculptor, like sculptures for people who have way too much money (laughs). At his metal shop, I asked him if he could make some round drum shells. The first question being, “How round can you make them? It has to be pretty uniform.” Larry figured out a way to make the shells truly round and how to weld them. He was my supplier for my heavy brass shells for a while. I did do a few shells out of stainless steel, but 90% were brass. We probably only made about 30-40 shells with Larry, probably closer to 30, so they are pretty special.

After that, I started making the Big Black drum. That was the first drum I really hit big with… In the past, Guitar Center was buying some metal drums from Lee Smith (Drum Paradise). Lee was getting WorldMax shells, putting on some tube lugs, throw-off and hoops and selling to GC; but they cost a fortune. Guitar Center wanted to sell a bunch of them but Lee was pretty limited in what he could do. Jeff Lorenz (Guitar Center) called me up and said, “I’ve got this opportunity. You want to give it a shot?” I said, “Sure!” So we got everything priced out and I was able to beat his price by quite a bit. I think the first order for GC was for something like 40 of these drums. It was a pretty good order. They were selling really well. Then I found out that over in Taiwan, there was really only one company that makes brass shells for just about everybody. The company I deal with over in Taiwan, I asked them if they could get this shell (I sent them a picture) and they said, “no problem.” That’s when we started doing the Big Black, giving it a name and its own tag – that’s how the Big Black came about.

Then GC came to me and said, “We’re looking for a snare drum that looks like its been buried in the mud for 100 years – Can you do something like that?” I said, “Yes, I’ve been doing that for a long time. Some of the brass shells I did back in the day with Larry I would do a patina finish on.” I got in touch with the company in Taiwan and said, “I need these shells and I need them raw.” They said, “Ok, sure - no problem.” I got some samples sent over and then figured out how I could do the patina finish in a production mode, doing batches at a time instead of just one. I figured that out and started making the 7 X 13” patina brass snare. The first order for these from GC was for 400 of them. To date, we have probably made close to 10,000 patina brass and 18,000 Big Black snare drums. It’s kind of like our Pork Pie thrones. I keep saying every year when I see how many we ship, “one day we are going to run out of butts in the world.”

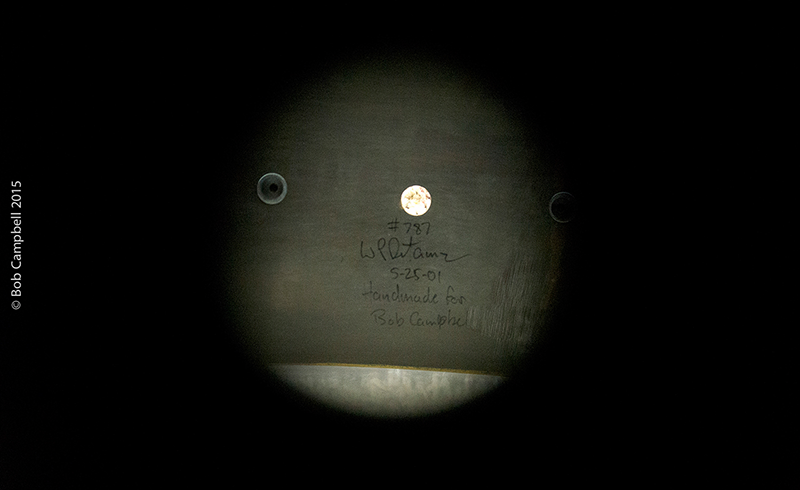

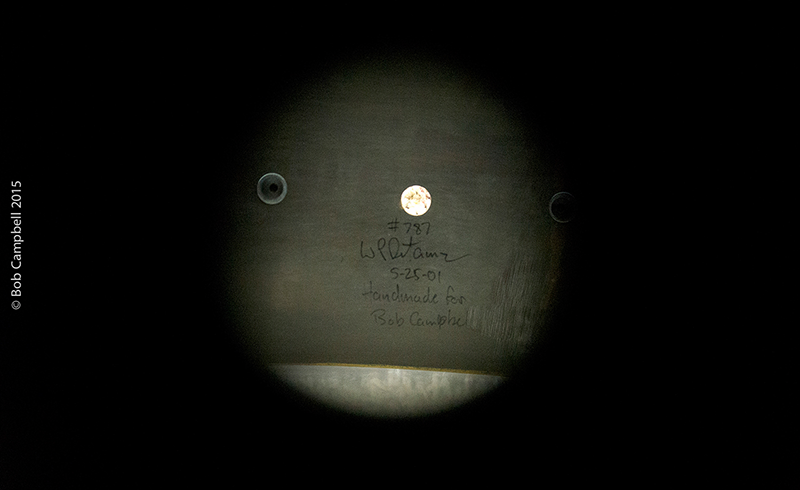

In 2001, we met and had a great discussion about drums. I wound up buying a 6 X 13” limited production, heavy brass Pork Pie snare drum (inside the shell, dated May 25, 2001; #787). Can you tell me more about these brass drums?

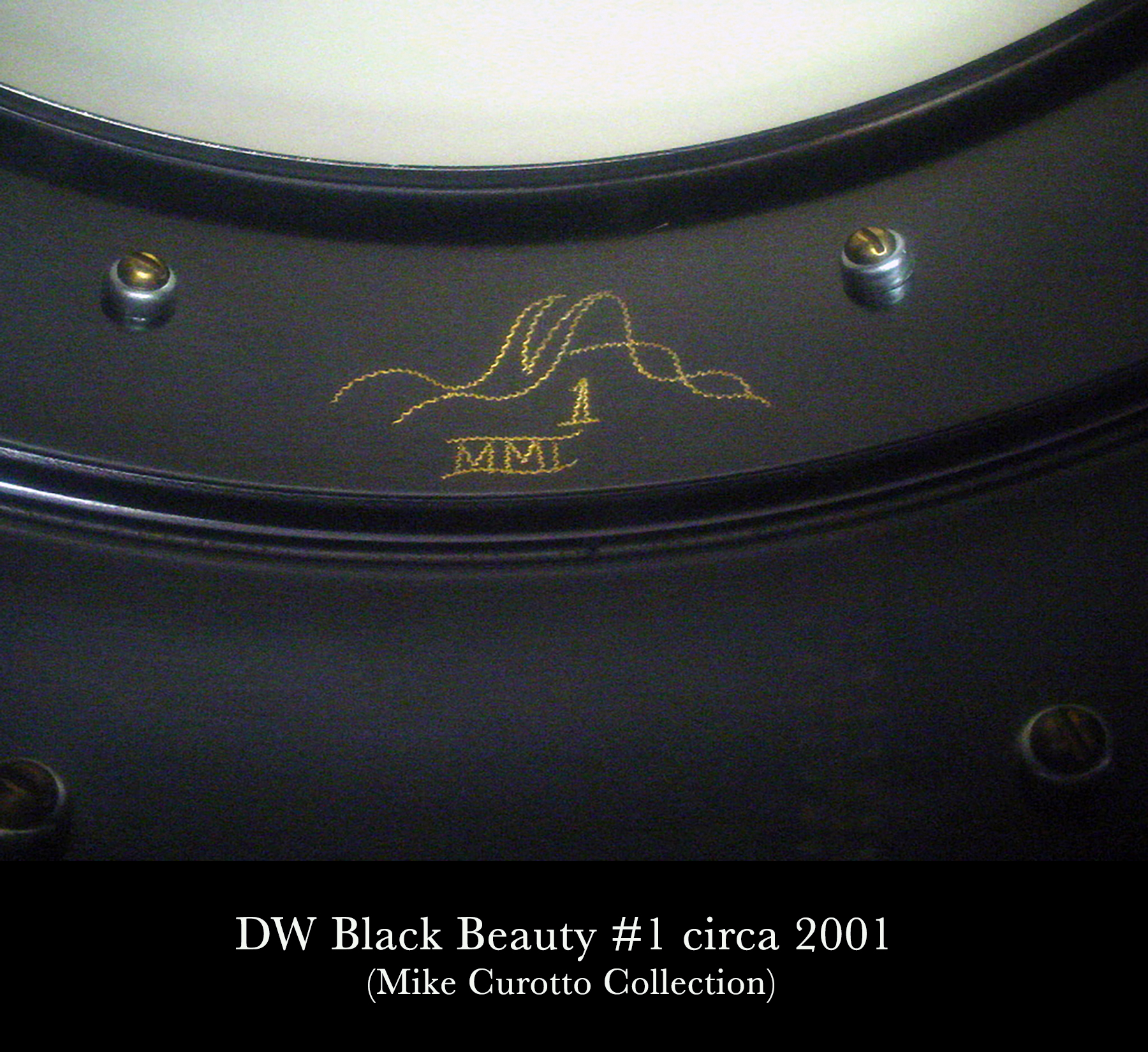

[Bill] “That particular drum was one of the limited shells made by Larry. The shell is a 1/8” brass plate that’s rolled and welded. At that time (2001), there was no WorldMax where you could go and get shells. If you wanted these heavy brass shells, you had to figure out how to make it. You couldn’t go out someplace and buy a brass shell. If we made a thin wall brass shell, say around 1mm thickness like a brass Supra or WorldMax shell, we’d need the tooling to bend over the edges – this is what keeps those shells round. Tooling for something like that was a huge amount of money. Larry’s thicker shell gave it stability, keeping it round without the special tooling. It wound up sounding great. The way I cut the bearing edges and put my snare beds in. I had a Makita grinder to get the snare beds close to where I wanted them and then I used a hand file to get them the rest of the way. It’s a lot of work. First, I get the contour the way I like it, then round it over and finish it by sanding it by hand. Sanding brass is not easy. For my early drums like this, I designed my own (hourglass-shaped) lugs that were made out of solid brass and my own throw-off (with small baseball bat arm attached to a cylinder) and butt plate, which were also solid brass. Later, when I got to making production drums, the cost was just way too high at that scale. For example, by the time I had the lugs buffed and chrome-plated, my cost in just one lug was $10; the throw-off and butt plate was around $80 – and that was back around 1995-2000! So I decided to go the direction of cast lugs for mass production. I do have a couple of the lugs and throw-offs left in my shop but I couldn’t imagine what the price would be now because of the cost of raw materials rising so much over the last 10 years. Even so, I don’t know of any machinist who could keep up with the numbers we do now.

Of the heavy brass snares, I made one 3 X 13”, a couple of 4 X 13” and 4 X 14”, bunch of 5 X 14” and 6 X 14”, a couple of 5 X 13” and 6.5 X 13”, and one or two 7 X 14”. We also made a couple of 10” snares, and some 12” including one run of stainless steel (12”, 13” and some 14”). That was the only time we did stainless steel because drilling 1/8” plate stainless steel was almost impossible; we were snapping drill bits. I remember we did one 5 X 14” bronze shell.

I started making these brass drums for guys around town. Matt Sorum has a couple of them. He used to buy snare drums all the time from me. I know Duff McKeagan (bass, Guns N’ Roses) has one in his studio; I believe Slash has one in his studio, and Mike Fasano (drummer for Warrant, Don Felder, Tiger Army and Gilby Clarke) has a couple that he rents out. Mike Bordin (drummer, Faith No More) - I think we made him 2-3 of these brass drums. He used one of these in the studio and loved it. He ordered one for the road and one he could have in his trunk as a back-up. I happen to have brass drum #1 at my place, a 6.5 X 13”. They started being used on records here in L.A. Back at that time, it was easy to go down to a recording studio with 10 snare drums, like when Guns n’ Roses were around, have Matt play them when they were recording. What better way to hear how a drum sounds than having Matt Sorum play it and Mike Clink producing?”

What’s your personal favorite snare drum?

[Bill] “I always loved solid shells. One of my personal favorites is a solid, steam-bent oak, 7 X14”. I gigged for years and years with it. I’m a meathead rock player. I used to be such a knucklehead for Radio Kings; that’s what I had mostly in my snare drum collection. Those drums had a 60-degree inside edge on them. That’s why I do all of my solid drums with a 60-degree edge on the inside and a round-over counter-cut on the outside. They sound fabulous.”

Any new snare drums from Pork Pie for 2015?

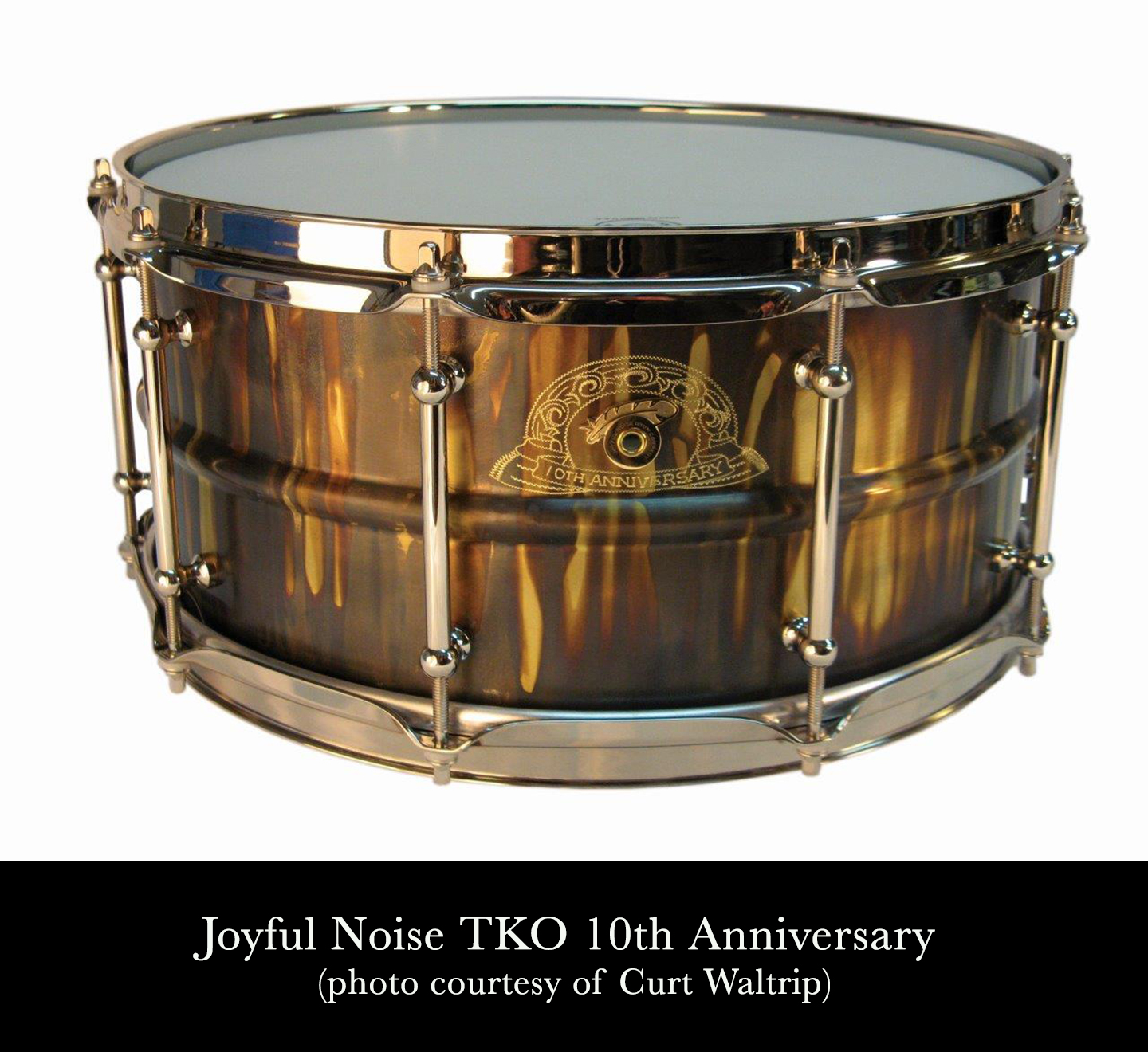

[Bill] “One of the drums we introduced at NAMM was the Porktone snare, which is a bell brass shell, 1/8” thick, and limited release (25) in only 6.5 X 14” size. They come in a brushed finish or custom high gloss lacquer over the top. This drum is a combination anniversary celebration for Pork Pie (28th Anniversary) and Soultone cymbals (10th Anniversary). On the badge, it says, “28 – 10 Anniversary snare”. I’ve been doing business with Iki Levy from Soultone cymbals since before he started Soultone cymbals, when he had a drum store. We thought, “How cool would it be if we made a snare drum together?” At first, we tried to make a drum shell out of cymbal material. We had a mold made over in Turkey. They were trying to make us a shell but they ended up being very brittle; that was a no-go. So we wound up getting a cast brass shell from Taiwan.

Another drum we have coming out around the end of July, early August, is the new Pig Iron 6.5 X 14”, 8-tube lug snare, and as the name states, the shell is made out of iron. The shell is thin-walled, rolled and welded, with a bead in the middle. It has a folded over bearing edge with rolled in snare beds. It looks like a Black Beauty snare drum shell but made out of iron. I’m doing them in two finishes: one is raw, polished iron and the other is a stain finish plated in tin. Both are clear-coated with lacquer so they don’t rust. I’m really excited about these. My favorite is the polished shell because it looks like it’s polished graphite. It’s really, really cool. These snares have the attack and body of a steel-shelled drum, but then it’s got the dryness of an aluminum drum.”

With regard to your drums, what has been your career goal?

[Bill] “Honestly, I wanted to make drums that somebody would go into a pawn shop or vintage drum store 50 years from now, find something that I made and say, “Hey, these are really cool! This guy made great stuff back in the day.” Like you or me going into one of these places and finding a chrome over brass snare drum the 50’s - that same type of feeling.”

It’s been a pleasure to get to know Bill better over the years and share our love of drums. He seemed quite pleased and honored to know that I still have and treasure my Pork Pie brass drum purchased so long ago. I do think it will be one of those prized and collectable snares 50 years from now. Perhaps it will be some drummer’s great find and they’ll ask – “Who built this amazing brass snare drum? I think these are pretty rare!” Hopefully, they’ll look in the Not So Modern Drummer archives and enjoy learning about an exciting chapter in our drum history; the story of the great Bill Detamore and Pork Pie Percussion. And somewhere, Bill Detamore will be smiling…