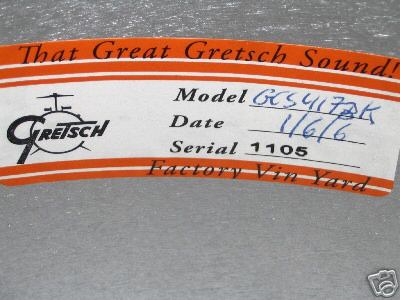

In 1983, on their stand at the Frankfurt Trade Fair, in stark contrast to the majority of drum manufacturers – who in Tama’s case had three floors of displays – Gretsch had one drum kit! A jazz kit, finished in Bird’s Eye Maple with gold plated fittings. A numbered, limited edition with a special new badge and every drum personally signed by Charlie Roy as part of a series of one hundred kits to celebrate the hundredth birthday of the company. According to the Gretsch staff, this was not a production run: every kit would be ‘made to order’ to the specifications of the customer. No brochure was produced, all that was shown to the dealers of the world were photographs of the three wood veneers available and after that it was up to the customer to say what sizes were required. The other two woods were Burl Walnut and Elm Burr. The drums were fitted with specially commissioned heads from Evans in a mirror gold finish. Even the snare wires and the drum key were gold plated. Any of the three finishes were available with chrome-plated hardware if desired. Each of the drums was given a special silver badge inside the shell that identified it with the set: in the case of my seven-piece kit (set #19) the bass drum was 1 of 7, while the snare drum was 7 of 7. The new outer badge featured the set number and also Charlie Roy’s signature in gold on bronze. Alongside all of this a customized satin tour-jacket was included, and it featured your name under the Gretsch logo on the front, and on the back was “THE CENTENNIAL” and an embroidered depiction of the kit. This meant you could flaunt ownership while the kit stayed safely in the house. Truly a collectors dream!

Needless to say, the quality of the finish of these drums was nothing short of exemplary. The use of Elm Burr veneer for instance, sourced in the Carpathian Mountains, made the cost fantastically high compared to a standard maple finish, so the lacquering and polishing were accordingly exceptional. The pride and attention that the staff normally took with Gretsch kits was always of the highest standard, but they still managed to ‘go the extra mile’ with this birthday series. The move to DeQueen, Arkansas had put the Gretsch factory in the heart of the American furniture belt, and consequently, the standard of wood finishing was superb. These were people who understood the treatment and development of wood and took enormous pride in the quality of production. To apply quarter-sawn veneers to the drum shell cylinders was an astounding achievement! An article in Modern Drummer magazine back in 1983, detailing a visit to the factory, left us in no doubt just how much care was taken over the finish and that these were exactly the right people to achieve such a result.

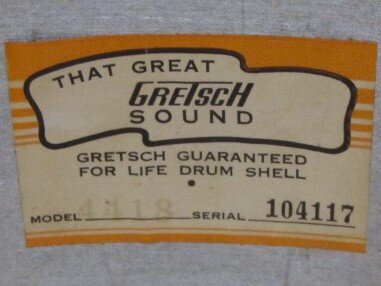

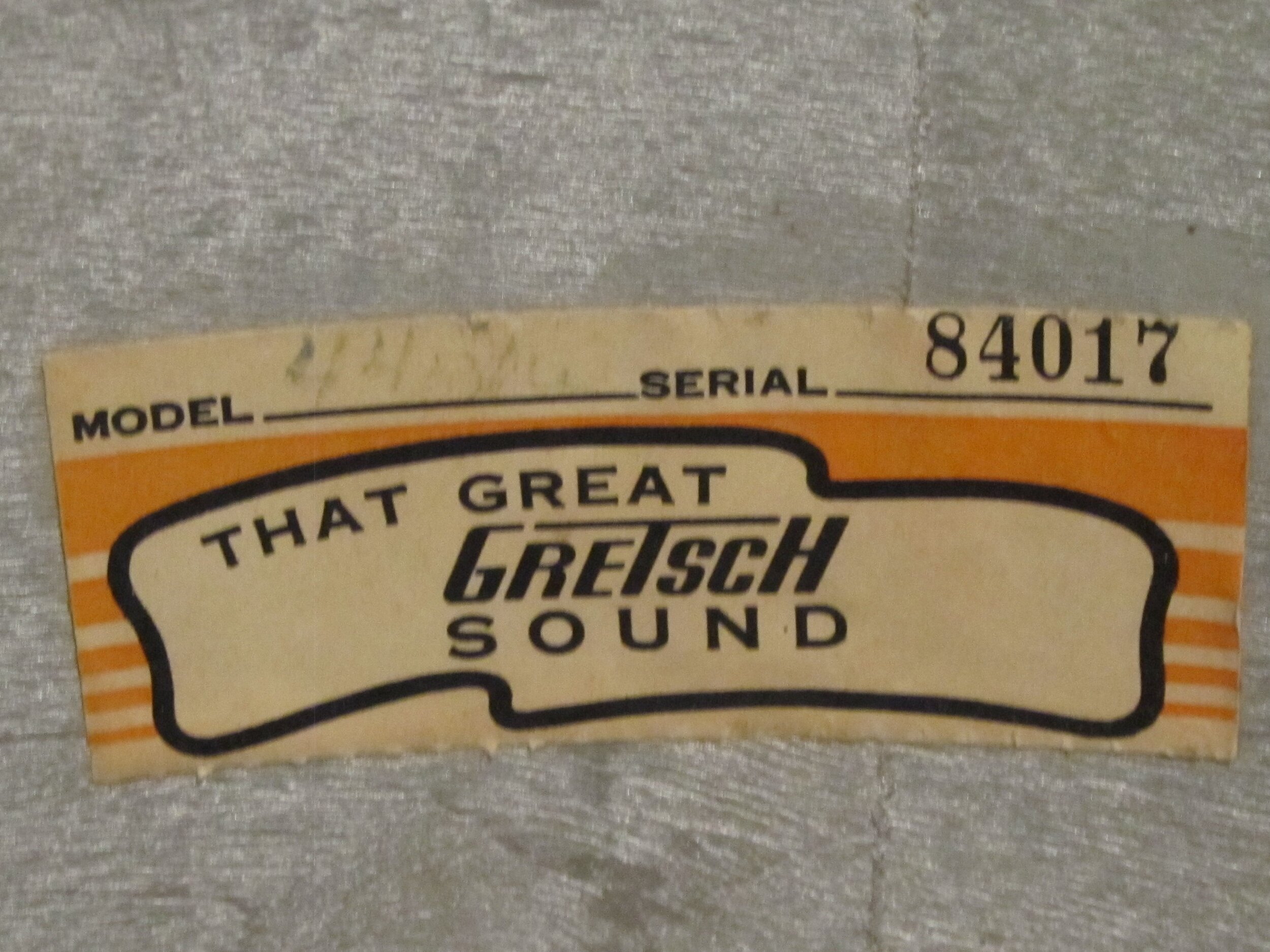

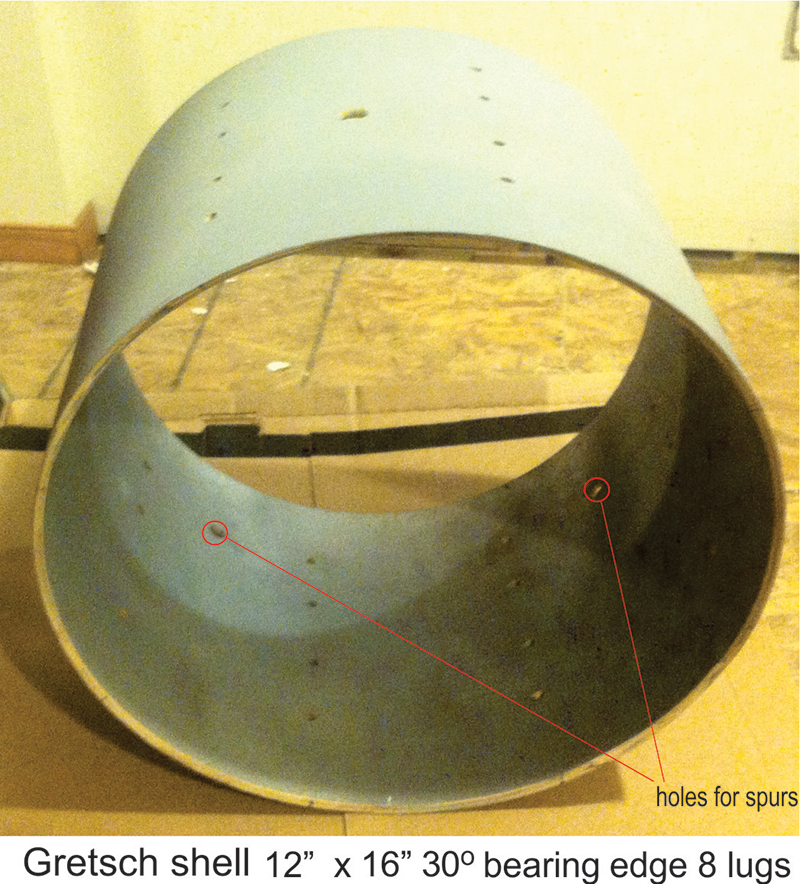

John Sheridan, in his article on the series for Classic Drummer, remarks upon the curious difference in the sound of the drums produced at the DeQueen plant and the subsequent demand amongst cognoscenti for shells from that period. I recently set about establishing the exact shell construction after a question was asked on the Gretsch Woodshed forum and discovered that my shells are actually thinner than normal Jaspers supplied to Gretsch in DeQueen at that time – even including the outer veneer – at 5 instead of 6mm, and effectively only five-ply rather than six. The ply material and grain orientation followed the standard Jasper format for DeQueen Gretsch; however, this generated a separate article to explain fully. The top and bottom of it all was that the Centennial construction was actually different again to the current production models and is one very thin, unreinforced shell.

If you think that all of this was a lot to offer the drummers of the world, and demand would obviously far outstrip availability, bear this in mind: back in 1985 the cost of a seven piece power-tom rock kit with an 8” snare and a 24” kick but without any hardware other than the tom-tom holders and their posts was $7,800. This was definitely an “exclusive” edition! Unfortunately, for reasons best left in the boardroom, Mr. Roy was forced to relinquish the presidency of the company which was returned briefly to Baldwin and the task of signing the badges was assigned to marketing manager Karl Dustman, before the company was once again returned to the Gretsch family’s hands.

My kit had been ordered by the owner of an instrument shop in the San Fernando Valley. He had intended to play the kit himself, but after waiting over two years for its delivery he adopted a DW instead. So when, in 1985, the kit finally arrived, he put it in the window and offered it for sale. As he was piling it up I arrived, saw the kit, walked into the shop and bought it there and then. As I said, the recommended retail price was $7.800.oo but I got a good deal because he had not even been invoiced for the drums and I was standing there with cash in my hand. I saw four other Centennials on sale in shops around LA during ‘85 and ‘86 – two featuring the alternate finishes – but I also sensed a certain blasé indifference to their presence: perhaps because of the price, and perhaps because this was the era of electronic drums, and wood was seen by many as ‘Jurassic’.

One hundred is actually quite a high number, considering what an exclusive project this was; plus, Gretsch was actually sitting in limbo all during this period – effectively without an owner – while the family got all their ducks in a row and were able to buy back the company at last. I don’t think the world had any idea how close we came to losing Gretsch forever; without the concerted efforts of the family that is precisely what would have happened. In the midst of all this broo-ha-ha it is not surprising that the records of sales and ownership were lost. I never got my jacket – that is for sure.