Understanding Ludwig’s Use of “Anti-Galvanic” Stamps and Stickers on Chrome Drums 1968 - 1984

By Richard E. Gier © 2021 – All Rights Reserved[i]

Ludwig utilized two different types of stamps and three different stickers to indicate that the anti-galvanic finishing process was used on its chrome-plated shells. By gathering information from chrome-plated drums and exchanging emails with the president of the company which provided plating for Ludwig, a timeline of the different stamps/stickers is developed. These interior stamps/stickers are another useful tool to authenticate and date vintage Ludwig drums.

In the late 1950s, Ludwig introduced to its lineup a chrome-plated brass shelled snare drum - the Super Ludwig. By 1963, the Super Ludwig had morphed into the chrome-plated “all metal” Supra-Phonic 400 with a shell made from an aluminum alloy, later branded as Ludaloy. Through the rest of the 1960s until at least 1984, Ludwig’s chrome-plated Ludaloy shells were used for several models, including the Supra-Phonic, Super Sensitive, Piccolo, and Standard (Ludwig’s second tier offering from 1968-1973) model 101 snares. A number of chrome-plated brass shells are also documented during the 1970s.

Without getting too deep into the metal plating process, for the purpose of this article one need only understand that anti-galvanic methods are employed to prevent a corrosive reaction between dissimilar metals. In the case of Ludwig’s chrome-plated Ludaloy shells, anti-galvanic finishing involves covering the aluminum alloy with layers of nickel and copper before adding the chromium layer. If not successful, the aluminum alloy corrodes and pushes the plating off of the surface of the alloy, resulting in the pitting, or “chrome acne,” which is all too familiar to collectors of Ludwig drums of this vintage.

Chrome-plated brass drums generally did not develop pitting, as brass is much less reactive. Ludwig’s chrome over brass shells from about 1958 through 1963 did not receive any special type of stamp or marking. Ludwig’s chrome-plated Ludaloy drums also received no marking from about 1963 through about the middle of 1968. Then, for no known reason, there began a progression of markings – stamps and stickers – inside of the shells which indicate that the chrome plating process in use was an anti-galvanic process and later, that this process was “Reliable.”

It turns out that while the plating process was not totally reliable, the company doing the plating was. Reliable Plating Corporation[ii] is a family-owned business which is still in operation. Reliable is located on W. Lake Street near N. Ashland Avenue, about two and a half miles from the 1728 N. Damen Ave. building where Ludwig manufactured and assembled drums until moving to North Carolina in about 1984. Jim Greenwell, current president of Reliable, started working for the family business in 1965. During his early years with the company, Mr. Greenwell spent time on the plating line. He recalls plating aluminum and brass shells for Ludwig. He remembers that snare shells made up most of the work done for Ludwig. Mr. Greenwell is sure that Reliable plated a majority of Ludwig’s chrome shells, although it is not clear if Reliable was Ludwig’s sole source of chrome plating. Mr. Greenwell recalls a progression of stamps and stickers that were added to the shells. He even recalls that Reliable coined the name “Ludaloy” to tie the anti-galvanic process to the Ludwig name. The bulk of Reliable’s work for Ludwig ceased when Ludwig relocated out of Chicago.

Data Collection about Anti-Galvanic Stamps and Stickers

Although Mr. Greenwell did not recall all of the specifics, information gathered about the markings inside numerous chrome-plated vintage Ludwig drums suggests a fairly orderly progression through a series of different stamps and stickers on the interior of Ludwig’s shells. In September 2014, I began recording information on the anti-galvanic stamp/sticker information on chrome Ludwig drums that I encountered. Many sale listings have incomplete descriptions or lack pictures of the interior of the shell, so no information is available about the anti-galvanic stamps/stickers on a large number of drums offered for sale. Further, my list contains only a small percentage of the Ludwig drums produced in the relevant time frame. Therefore, the relatively small number of drums used for this study represent a much larger number of drums which possess an anti-galvanic stamp or sticker.

A total of 1,500 chrome-plated main line drums from 1968-1984 (the era when anti-galvanic stamps and stickers were used) are on my list, with 232 known to possess an identifiable Anti-Galvanic stamp or sticker. A total of 38 chrome-plated Standard drums from 1968-1973 are in my list, with 18 known to possess Anti-Galvanic stamps or stickers. This creates a group of 250 drums from which we can learn about Anti-Galvanic stamps and stickers and construct a timeline. As more reports are documented, this interesting piece of minutiae about vintage Ludwig drums can be more fully and precisely understood.

Caution - As with any date estimating tool, it is important to understand that serial number and date stamp ranges shown below represent known examples and are not absolute or definitive start and stop points for when the various stamps/stickers were in use. They are known reports of drums with the particular stamps or stickers. Others exist so these boundaries are approximations. That said, there appears to be very little overlap in serial number and date ranges for the three most common indicators. One infrequently seen sticker is a little harder to precisely place, as only one example is documented.

Anti-Galvanic Stamps and Stickers and Timeline of Their Use

1958(ish) – 1968: No Stamp or Sticker

No stamp or sticker indicating Anti-Galvanic plating process is present.

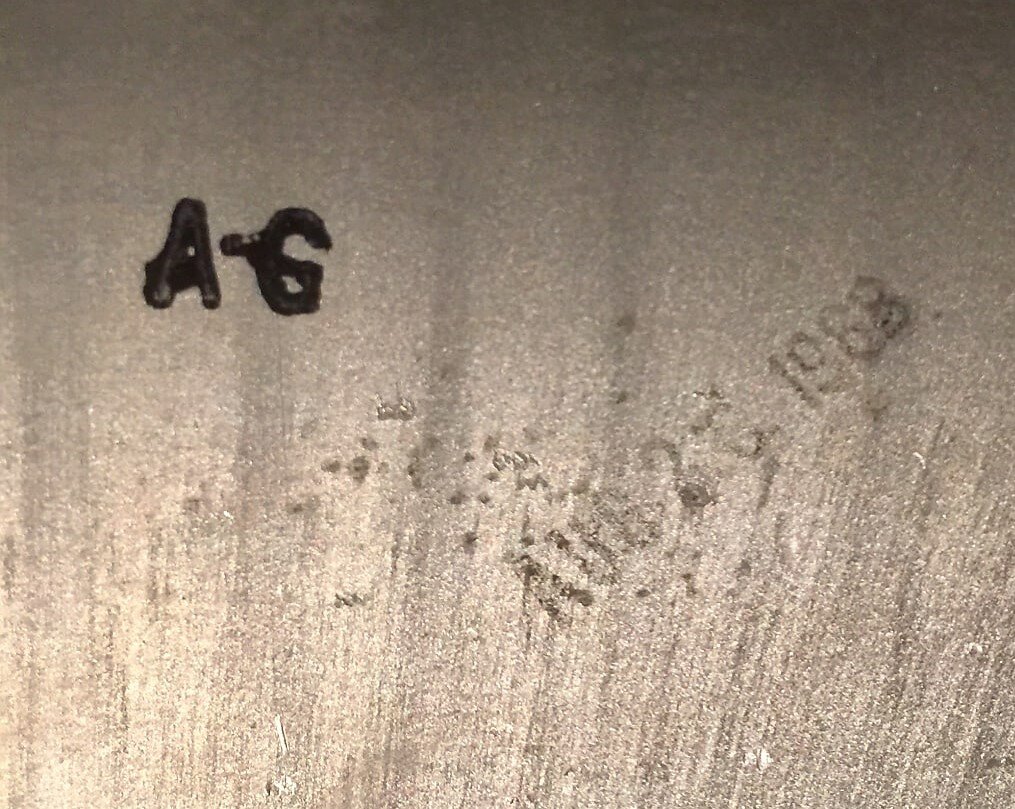

1968-1969: “AG” Stamp

Stamps with capital letters “A” and “G” were introduced in about mid-1968 and used for about a year and a half until the end of 1969, with one report in January 1970. The stamp appears both with and without the A and G separated by a hyphen – “AG” and “A-G”. (Both variations are grouped into a single title “AG” stamps for this article.) Black ink is used. Almost every report of an “AG” stamp is on a drum with a Keystone badge and one example is on a trimmed Blue/Olive badge. The “AG” stamp usually appears on same panel as the date stamp (when present) and a handwritten letter which is generally believed to be an inspector’s mark (when present). The “AG” stamp usually appears just once, but has been documented to be stamped as many as six times inside a single shell. Sometimes one letter is upside down relative to the other - “ꓯG” or “ꓮ-ꓨ”. There are four additional examples of other stamps using the same size and font of letters in black ink, including BGA, EGA, G and GC. Other variations likely exist.

Main Line Drums (Keystone and Blue/Olive badges)

Number of Reports: 31

30 Keystone Badge with Serial Numbers

1 trimmed Blue/Olive Badge with no Serial Number.

15 of these drums had complete date stamps.

Serial Number Range: 620797 - 747350

Date Stamp Range: AUG 12 1968 - JAN 6 1970

Alternate Stamps:

BGA (one example) – 691976, MAR 14 1969

EGA (one example) – 687374, APR 1 1969

G (one example) – 732551, OCT 22 1969

GC (one example) – 755178, JAN 23 19??

Standard Drums

Number of Reports: 2

Serial number 29078 and no date stamp - the A is inverted “ꓯG”

Missing badge with JAN 13 1970 date stamp - the G is inverted “ꓮꓨ”

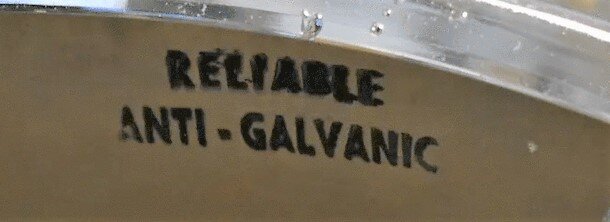

1970 – 1975(ish): “RELIABLE ANTI-GALVANIC” Stamp

In very late 1969/early 1970, the “AG” Stamp was replaced with a new much larger stamp which contained the words “Reliable Anti-Galvanic.”[iii] It appears in black ink and is most often is stamped twice, but sometimes only once. At times this new stamp is partially or fully covered by a paper label showing a model number and date stamp or Date Code. “Reliable” does not refer to the finishing process, but to the plating company which provided the chrome finishing.

Main Line Drums (Blue/Olive badges)

Number of Reports: 82

79 Serial Numbers on Blue/Olive badges

2 are on Trimmed B/O badges without the circle R ® trademark registration symbol

1 has a blank B/O badge with the circle R ® trademark registration symbol but no serial number

48 possess complete date stamps

10 have Date Codes.

Serial Number Range: 756319 - 1207444

Date Stamp Range: DEC 18 1969 - NOV 12 1971

Date Codes: 4272 (3 reports), 14727 (2), 21720 (2), 31720 (2), 58717 (1)

Standard Drums

Number of Reports: 16

Serial Number Range: 47319 - 87000, one without serial number

Date Stamp Range: DEC 3 1970 - DEC 3 1971

Date Codes: 21720 (two reports)

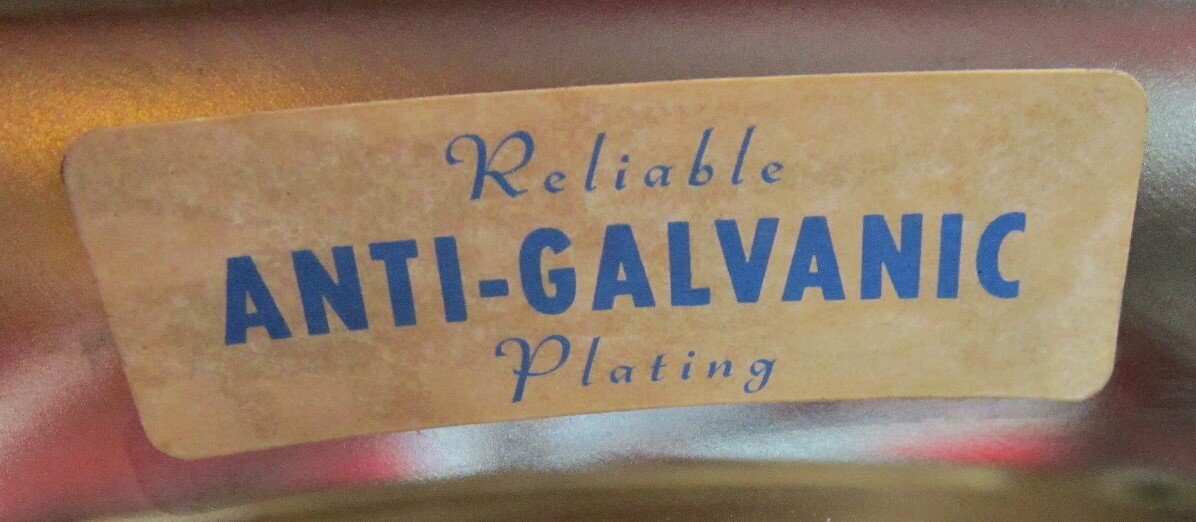

1974(ish): Rectangular “Reliable ANTI-GALVANIC Plating” white sticker with blue letters

This particular variation is not seen very often. It is a white sticker with the words “Reliable ANTI-GALVANIC Plating” in blue ink. One example has been documented, although undocumented reports of this label exist. It is inappropriate to define serial number range or time frame where this sticker should occur with just one report, but the serial number places this singular example in about 1974.

Main Line Drum

Number of Reports: 1

Serial Number: 1100985

1975(ish): Oval “’Reliable’ ANTI-GALVANIC” blue sticker with white or gold letters

This additional sticker design is also not particularly common. It is an oval shaped sticker with a blue background and gold or white letters. It displays the words “Reliable (in quotes) ANTI-GALVANIC”. Six examples are documented.

Main Line Drums

Number of Reports: 6, all with Serial Numbers

Serial Number Range: 1170023 – 1260485

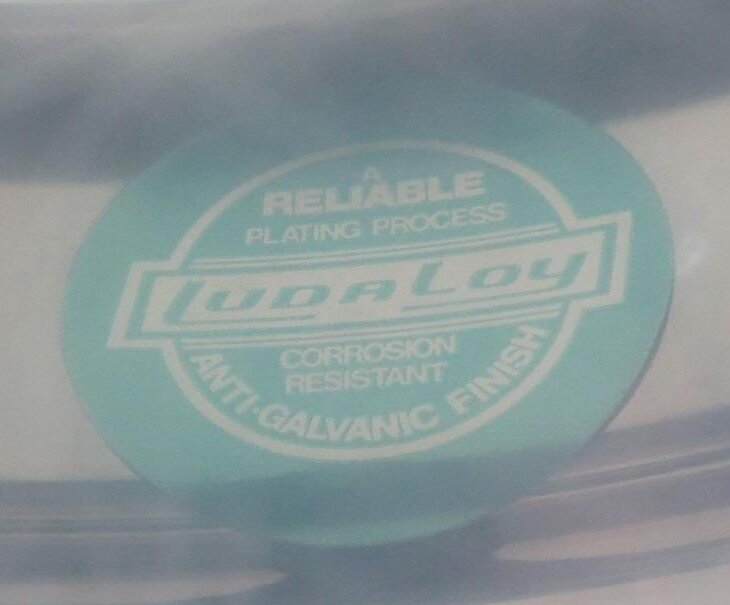

1976ish - 1980s: Round Blue Ludaloy Reliable Plating sticker

The final sticker was in use for many years and first appears in about 1976. It is round with a blue background and white lettering. This is the only stamp/sticker which indicates the shell material – Ludaloy. The presentation is a stylized design which mimics the block logo used by Ludwig beginning in the late 1960s. Along with the Ludaloy branding are the phrases “A RELIABLE Plating Process,” “Corrosion Resistant” and “ANTI-GALVANIC FINISH.” It appears that this sticker was in use until Ludwig relocated from Chicago to Monroe, North Carolina in about 1984. That move mostly ended the relationship between Ludwig and Reliable Plating.

Main Line Drums

Number of Reports: 110

109 with Serial Numbers

1 has no Serial Number

Serial Number Range: 1532560 – 3178025

[i] Photo Credits – These drum collectors graciously provided permission to use their photos:

“A-G” Stamp - Supersonic Music, Topeka, Kansas

“RELIABLE ANTI-GALVANIC” Stamp - Matt Jansen, Midwest Drum, Wichita, Kansas

Rectangular Sticker - Richard Blanchard, Mrfathead Drums, Arnold, Maryland

Oval Sticker - Supersonic Music, Topeka, Kansas

Round Blue Ludaloy Sticker - Richard E. Gier, author

[ii] Much thanks to Mr. Jim Greenwell and Mr. Coult Greenwell, his son, of Reliable Plating Corporation for responding to my requests for information and sharing some history with me.

[iii] Only one report of the new stamp overlaps with the “AG” stamp - a drum with date stamp DEC 18 1969 and a RELIABLE ANTI-GALVANIC stamp predates the last reported “AG” Stamp which had a date stamp of JAN 6 1970. One other drum with an “AG” stamp has a partial date stamp – JAN 23 19?? - which is likely from 1970.