The Slingerland drum company had offered a variety of painted lacquered finishes throughout their dominant years of manufacturing. This lacquered paint was made up of a nitrocellulose chemical base ingredient. The nitrocellulose properties included solvents and resins along with the use of lacquer thinners. As the solvents evaporate, the lacquer finish forms and completely cures. The automotive industry had utilized this same paint component for their production of auto finishes. This was the auto industry standard between the 1920s through the 1960s. Likewise, was the use of lacquer paint in the same formidable years with American musical instrument and drum manufacturers. The most common instruments that were lacquered were guitars, banjos, mandolins and of course snare drums as well as drum sets. Lacquer was a very durable and conforming paint product. The auto industry and musical instrument manufacturers would spray multiple coats of this paint to produce a brilliant finish. The factory workers would wet sand between each coat to lay down multiple coats. Then, buffing and more wet sanding would begin to produce a brilliant, durable lasting shine. One could achieve a beautiful high gloss, mirror finish using this technique. This process of lacquer paint was excellent to spray on both wood and metal surfaces. Also, this was the mainstay painting process for many years and is still being utilized on musical instruments produced today.

Some of Slingerlands most utilized and cataloged colors were "duco" or two-tone lacquer painted finishes. These Slingerland "duco" finishes were offered in the following choice of two tone colors: Black & gold, blue & silver, blue & gold, red & gold or green & gold.

These were some of the most common color options and combinations that were offered by Slingerland between the 1920s through the 1960s. Slingerland also produced "tri-color" or three color finish combinations as well, although these are much rarer and very few examples still exist today. Interestingly, back in this time period, pearloids and sparkling pearls cost a few more dollars than duco or lacquer finish drums as cataloged. Some drummers decided for the lacquer option because they were less expensive. They would be able to afford a better model snare drum or drum set.

During Slingerland’s pinnacle time of manufacturing a drummer could actually request a special color order that they envisioned. Some of these orders produced were for a "mono" or one solid color lacquered painted finish. These unique finishes were much more uncommon to find on Slingerland drums of this vintage era.

Here are four examples of Slingerland Radio King snare drums produced with "Solid" lacquer colored finishes.

The first example of a solid lacquer finish is this 1940s Radio King. The color is solid white. The shell size is "6.5x14", with a solid 1-ply maple shell. The hardware used is a 3-point strainer, simple butt plate, eight center streamline lugs along with full flanged rims. All hardware is nickel plated. The badge is the cloud variety.

The second example of a solid lacquer finish is this early 1950’s Radio King. Note, this snare drum has a more rare, exotic solid color. The finish is a beautiful turquoise hue that reflects the 50s era use of colors. You can also see this color being utilized in the automotive industry. An example of this can be found on a 1957 Chevy Bel Air and a 1959 Ford Thunderbird. Notice, the beautiful turquoise lacquer painted finishes on these 50s Vintage Classic cars. In this golden era, both the automotive and drum manufacturers focused on unique solid color combinations, complimenting this wonderful time period.

This Radio King comes equipped with a 5.5”x14”, solid maple shell. The hardware used is a 3-point strainer, two six hole extension bridges, a dual muffler and eight center streamline lugs. Also, full flanged rims complete this snare drum. In addition, this snare was ordered with beautiful chrome plated hardware. The badge is the pressed or dog tag variety.

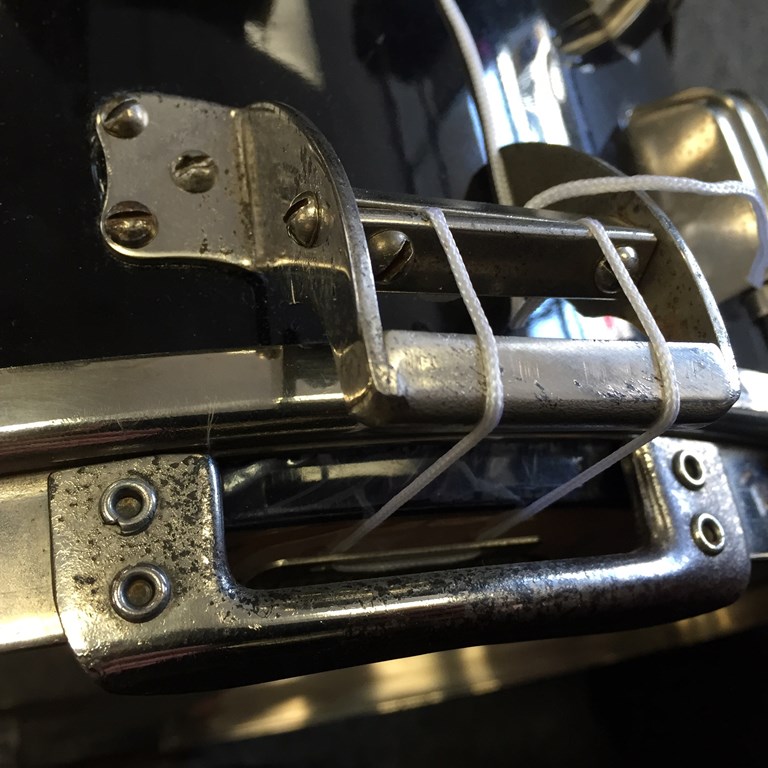

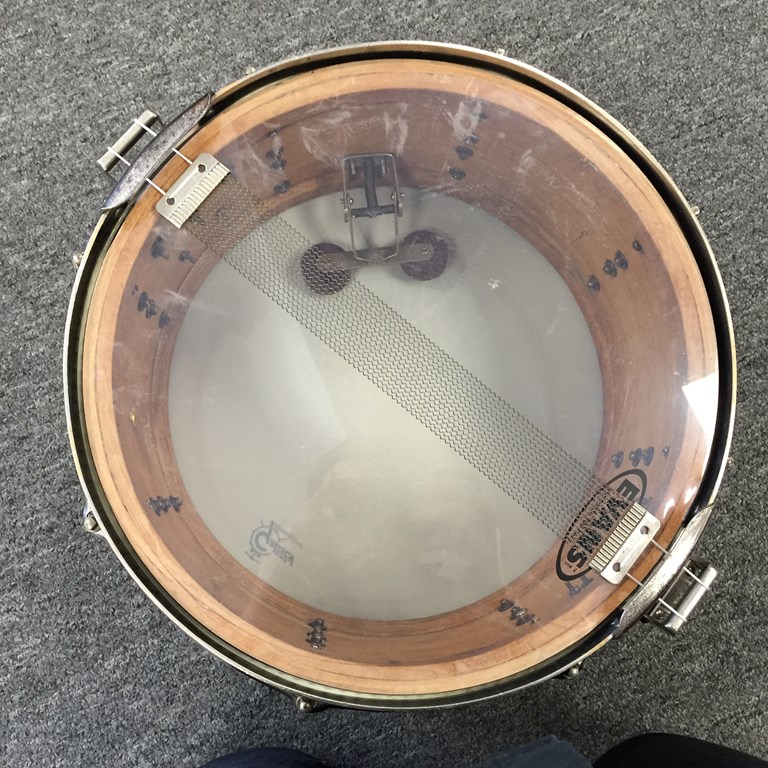

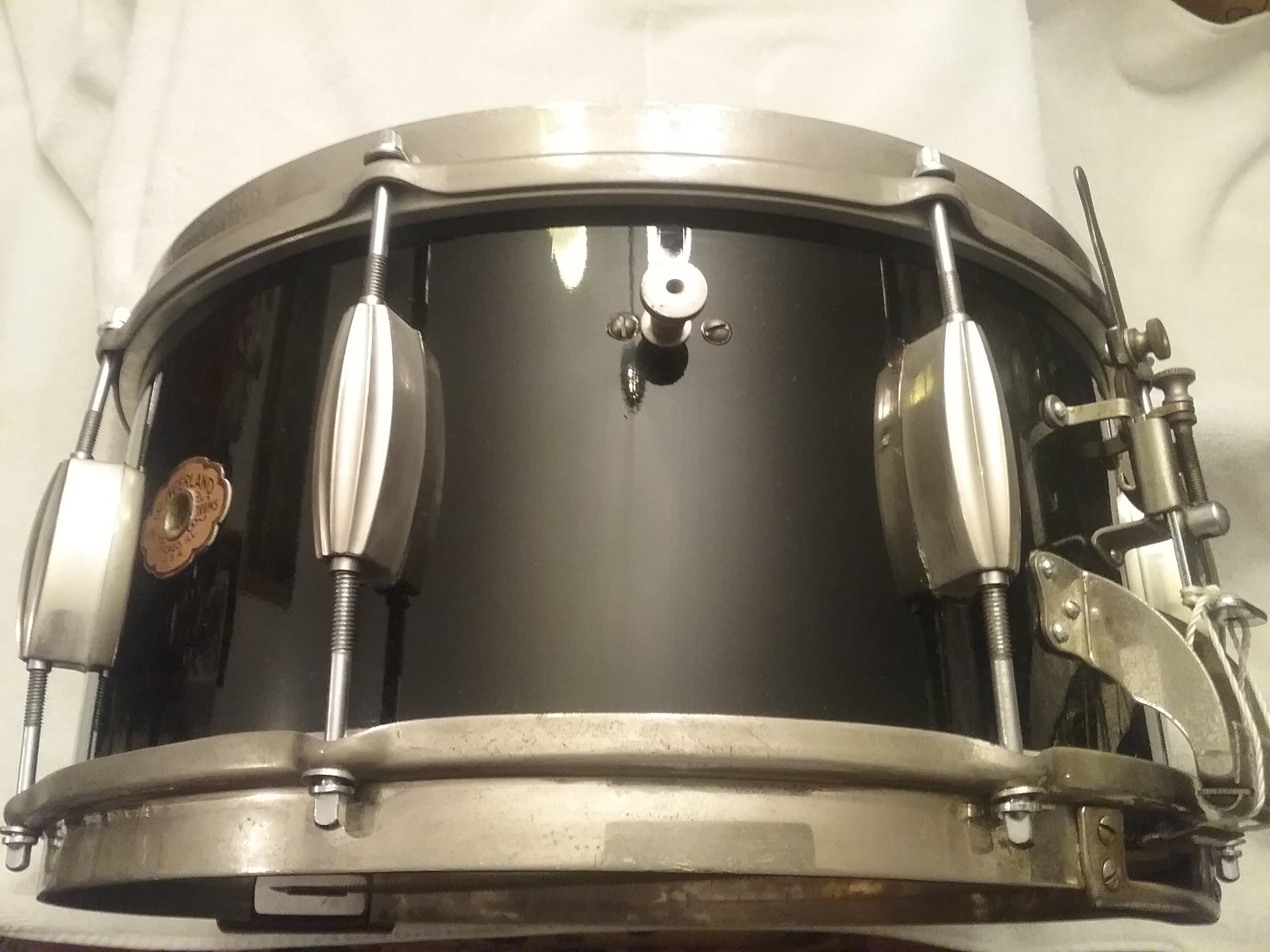

The third example of a solid lacquer finish is this 1940s Radio King. The color is Piano black. The shell size is 7”x14”, with a solid maple shell. The hardware used is a 3-point strainer, two six hole extension bridges, a dual muffler and sixteen small beavertail lugs. All hardware is nickel plated.

The fourth example of a solid lacquer finish is this 1938 Gene Krupa Model. The color is also piano black. The shell size is “6.5×14”, with a solid maple shell. The Hardware used is the early 3-point strainer, two six hole adjustable extension bridges, a dual muffler and eight streamline center lugs. The hardware is a combination of nickel and chromium which was a common practice at the Slingerland factory.

All of these unique Slingerland Radio King drums produced were a drummer's vision and requested special order. These wonderful examples are a testament to Slingerland's willingness to satisfy all of their customers. The American musical instrument, drum and automotive manufacturers utilized the same lacquer painting system. Even today, various manufacturers are still using lacquer paint for their products. This lacquered paint is now the preferred finish of our modern snare drums and drum sets. Many vintage lacquered snare drums and drum sets have stood the test of time because of its durable and unique chemical properties. As a result, these preserved examples of our past will be passed down from one drummer’s generation to the next.