One of the intriguing aspects of collecting vintage drums is discovering when your instrument was made. Estimating the age of a drum can be done more or less by examining its badge type, style of hardware, shell construction/composition and interior/exterior finish. If you’re fortunate enough, your drum might even have a date stamp on the inside of its shell. But unlikely as it may seem, the broadcast of one television show in early 1964 played an unwitting role in helping to date more closely one particular brand of drum. To see how the story unfolds, let’s go back in time to February 9, 1964.

It was the day the Beatles appeared on the Ed Sullivan Show. Their television debut ushered in not only a new era for rock and roll, but something more. With the name "Ludwig" painted on Ringo’s bass drumhead, it marked also the beginning of the Ludwig Drum Company’s largest boom in their production history. "Even though we stepped up our production, the orders for our drums came in faster than we could make them," said William F. Ludwig II who was then the company’s General Manager and Vice President.

This new surge in Ludwig’s production and sales coincided with a new government regulation enacted at about the same time (The regulation was brought to our attention by drum historian/insurance agent, Harry Cangany). These overlapping events would intertwine to have a direct effect on the collecting and dating of 1960s Ludwig drums. Prompted by the insurance industry, the new regulation mandated serial numbers on certain goods, including drums. "Up until then," said Mr. Ludwig, "some of our drums were date stamped and some weren’t - but none had serial numbers. Our dealers begged us to put them on, so we had our badge manufacturer imprint sequential numbers on the badges for all of our drums."

With the debut of serial numbers, Ludwig helped the dealers comply with the new law. But unforeseen then to the drum company, these serial numbers would also be a key to unlock the mystery of how to date post-1963 Ludwig drums that weren’t date-stamped. Though in actuality, the way to pin down the elusive age of these drums would call more for the sharp pencil of a record keeper than the skill of a Sherlock Holmes.

Motivated by a growing number of customer inquiries about dating 60s era Ludwig drums, as well as our own historical interest, we took on the task of record keeper. We began in the late 1980s by monitoring all of the 60s Ludwig drums that came into our shop. Thanks to the production boom of the 60s, we had a large sampling of drums, which provided enough data to do our research. When we found a drum with both a serial number and complete date stamp present, this data was entered into a serial number index. We hoped that, in time, the index would reveal a consistent chronological order in the serial number sequence. The reasoning for our optimism was that since the serial numbers were imprinted on the badges in a sequential order (of lower to higher numbers) and since the badges were installed over a duration of time as represented by the date stamps inside of the shells, a direct relationship between the serial numbers and date stamps was inevitable, even though the Ludwig factory did not intend it.

As our record keeping continued and more serial numbers and dates were added to the index, the correlation between them became increasingly evident. Although we did find some discrepancies in this correlation - which we'll discuss later in this article - a general pattern emerged. The serial numbers increased as their corresponding date stamps moved forward in time.

In a recent conversation with Jack Lawton, restoration specialist and owner of the Lawton Drum Company (Sudbury, PA.), I discovered by chance that Jack had, over a 10 year period, also developed a serial number index like ours. We decided to exchange and compare indexes. To our mutual relief, we found that the serial numbers and date stamps corresponded with one another and that the sequence of the serial numbers in both indexes followed the same general path through time.

Let’s have a look now at some numbers. Below is Ludwig 1960s Serial Number Time Chart #1. It contains particular number/date stamp pairs chosen from our original serial number index because they serve as good representations of the chronological trend of the serial number sequence. By using this chart, you will be able to know in most cases the year, and time frame within the year, that your 1960s Ludwig drum was made. For additional clarification we have included a few serial number/date stamp pairs provided by helpful collectors.

Here’s how to use the chart:

Taking as an example a non-date stamped drum with the serial number of 718,321, lets first find the proximate serial numbers to 718,321 - which are 689,430 and 743,080 respectively. Next, check the corresponding dates to these serial numbers - which are February 26, 1969 and September 4, 1969. These two dates indicate the general time frame when our non-date stamped drum was made.

Keep in mind when using the chart that due to Ludwig’s production, assembly and order-fulfillment procedures during the 60s (discussion following the next chart) it’s not uncommon to find a moderate margin of discrepancy in the serial number/date stamp relationship. For this reason, the production date of the drum you’re dating could actually be several months earlier or later than the chart indicates.

I once asked Mr. Ludwig why only some of the shells were date stamped? He explained, "The reasons varied over the years. Sometimes it was because we wanted to accommodate certain dealers who didn't want the dates. Other times it was to keep up our production speed so that we could keep up with the demand. And sometimes it was just because the stamp pads ran out of ink."

Furthermore, not all of the dates that went on the drums stayed on the drums. Dick Gerlack, who recently retired from the Ludwig Drum Company as their quality control manager/ trainer/ buyer, was with the drum company from 1960 to 2001. He pointed out to me that because Ludwig used non-indelible ink for the stamping of the dates, some dates were inadvertently smudged or removed - in part or whole after the drums left the factory by drum owners while cleaning their drums.

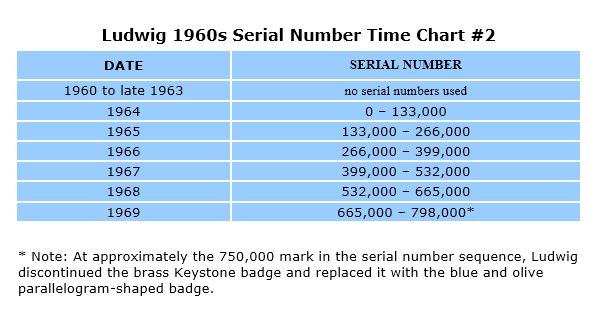

The next Chart #2 gives an overview of the serial number sequence as it progressed from one year to the next. Using a simple formula, we have estimated, to the nearest thousand, the average count of serial numbers used for each individual year between 1964 and 1969. For those of you who enjoy mathematics, the formula is: 800,000 (the approximate aggregate of serial numbers used 1964 through 1969 based on our serial number index), divided by six (the quantity of years spanning 1964 through 1969), equals 133,000 (the average yearly increase in the serial number progression).

Based on this calculation, Chart #2 shows a cumulative yearly growth of 133,000 serial numbers from 1964 through 1969. Since each one of these serial numbers corresponds to one individual drum produced, then our 133,000 yearly estimate, if correct, would have to reconcile with Ludwig’s yearly tally of drums produced during that same period. To verify our calculations I asked both Mr. Ludwig and Mr. Gherlach how close our yearly serial number estimate was to the drum company’s yearly drum production output. Their respective answers were, "The 133,000 figure is extremely close to what we were doing" and "It’s right in the ballpark." When using chart 2, keep in mind that these serial numbers are close indicators only, i.e. the serial numbers marking the beginning and ending of each year cannot be distinctly established due to Ludwig's factory procedures just mentioned, and the discrepancies that those procedures caused in the serial number/date stamp-relationship.

To understand the cause of discrepancies, let’s go back in time to the Ludwig factory of the 1960s. The manufacturing division at Ludwig was divided into two basic departments: the wood shop and final assembly. Shells were constructed, wrapped in mylar, and date stamped in the wood shop. Then the shells were drilled and hardware, heads and badges were installed in final assembly.

The date stamp didn’t determine when a shell would be sent to assembly. "It was its size and finish," Mr. Ludwig explained. "The shells were made in advance of the orders coming in. Sometimes we had thousands of undrilled shells all stacked up on shelves. When assembly needed a certain size shell in a particular finish, it was pulled from the shelf and sent off to them. We didn’t pay any attention to the date stamps and if a shell wasn’t needed to fill an order, it stayed on the shelf for days, weeks or months, sometimes years.”

Due to the time lapse between when a shell was date stamped and when the badge was installed, some of the drums assembled on the same day with closely matching serial numbers had date stamps that were months apart from one another It also meant that some of the drums with production date stamps close to one another, would have badges with serial numbers that were tens of thousands of digits apart.

Further adding to the creation of discrepancies was Ludwig’s method of storing, retrieving and installing badges. Mr. Ludwig explained, "Most of the time when a new shipment of badges came in from our manufacturer, we still had a few boxes of them left in stock, so we just stacked the new boxes in together with the old ones. When assembly needed more badges, we just took any box at random and put it on the assembly bench. We didn’t try to keep the boxes in order or try to install badges in order by serial numbers. Our main concern was to keep things moving."

Since there wasn’t any system of stock rotation whereby the boxes were used in the order received, I asked Mr. Ludwig about the probability of a leftover box or two stagnating for months at the bottom of a stack. Mr. Ludwig replied, "I would say in all likelihood that’s just what happened." At a production rate of about 11,000 drums per month, it meant that for each month that passed, the serial numbers on the unused badges inside of a stagnant box would fall 11,000 digits behind the progressing sequence of serial numbers. After a period of time, when the stagnant box was opened and the badges went back in circulation, the serial numbers on those badges would naturally be out of sequence with the others. For example, when a badge that was out of circulation for three months was eventually installed on a drum, its serial number would be lower than, and discrepant to, the more current badges being installed, by an amount of 33,000 digits. Refilling the assemblers’ badge bins was also a source of a limited amount of discrepancies. Since the bins were not always completely empty before being refilled, some badges remained at the bottom, stagnating there for a period of time before finally being used.

On one rare occasion we acquired a drum with a 1967 date stamp and a serial number corresponding to 1965. This was a much bigger discrepancy than any we had encountered. So, thinking the badge was unoriginal, I inspected its condition and grommet as well as the interior of the drum shell for signs that the factory original badge had been removed and replaced by the one on the drum. My inspection confirmed that the badge was original. The explanation of the cause of so large a discrepancy came unexpectedly during one of my conversations with Mr. Ludwig when he happened to mention this to me, "Once in a while we found a misplaced box of badges that was overlooked and sitting around the factory for a couple of years. So we opened up the box and used the badges." John Aldridge, then-editor of Not So Modern Drummer magazine, informed me that he had once found a Ludwig drum with a discrepancy of 5 years between its date stamp and serial number.

There was also a crop of late coming discrepancies that didn’t spring up until about October of 1969, when the three decade reign of the small Keystone badge came to an end. At this time the Ludwig Drum Company introduced their new logo, new badge and some new finishes. During this transition period, shells wrapped in the new finishes were stored together with the older shells wrapped in the older finishes. For a limited time, the new badges (parallelogram-shaped blue/olive color) were installed concurrently with the remaining supply of the older Keystone brass badges. This resulted in some drums having a new finish but old badge.

With the end of the 1960s Keystone badge came also the close of an historic decade in music; a decade that inspired unprecedented numbers of young people to take up a pair of sticks and learn to play the drums. The boom of the 60s also provided a generous supply of drums for those who, in the future, would become interested in collecting them and preserving our heritage. Little did Mr. Ludwig know the effects their role would have on the decades to come. Reflecting on the past he said to me, "No one thought of vintage drums or collectors when we were making all of those drums back then. I never dreamed I’d be talking to you now about all of this 35 years later."

----

© Copyright 2002 Vintage Drum Center, Inc. All rights reserved. Header image courtesy of Sundog Vintage Drums.